Types of Compressors And performance Management

Typically used compressors for most systems, vapor compression piston, screw, scroll, and centrifugal pumps. In a very small applications, such as window air conditioners and split air conditioners, small turning roller or lobed or piston compressors are used.

Compressors are constructed as Open, Hermetic and semi-hermetic (or semi bolts) compressors. In open-type compressor shaft extends compressor and connected externally Prime engine (motor or engine). In a hermetically sealed motor-compressor, the entire Assembly is encapsulated, only the lines of the refrigerant and the electrical connections expansion of the chassis. In the semi-hermetic compressors, until the motor and the compressor are encapsulated, the leaders of the compressors can be removed to gain access to pistons and valves for maintenance. The engine is also available for repair of clearing the latch plate.

In both hermetic and semi-hermetic compressors, refrigerant is in contact with the motor windings. So only Halocarbon refrigerants that have not attacked copper, can only be used, ammonia cannot be used.

Currently, ammonia compressors always open type.

Open-type compressors, tend to be more effective than the hermetic and semi-hermetic type, because the suction couple in hermetic compressor enters the engine cooling, resulting in super heating of vapor and thus requiring more energy to compress. However, the cooling system design can minimize the impact on energy consumption.

Rotary compressors, as a rule, suitable for a small fraction capacity machines, and window air conditioners. These compressors or roller blade or reciprocating type. The roller type compressor (Fig. 2.3), ice rink eccentrically mounted in a cylindrical space with spring cage. Low vapor pressure is shrinks and finally discharged into the condenser. Roller type compressors are manufactured up to 5 tons. In vane-type compressor (Fig. 2.4), the number of fans installed in slots eccentrically mounted rotor. The position of the blades is changed when the rotor rotates. The compression ratio is within about 7:1. Regulation of power Cycling the compressor on and off.

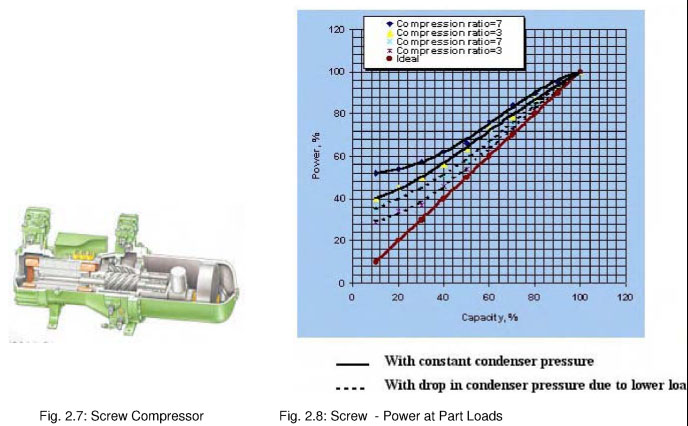

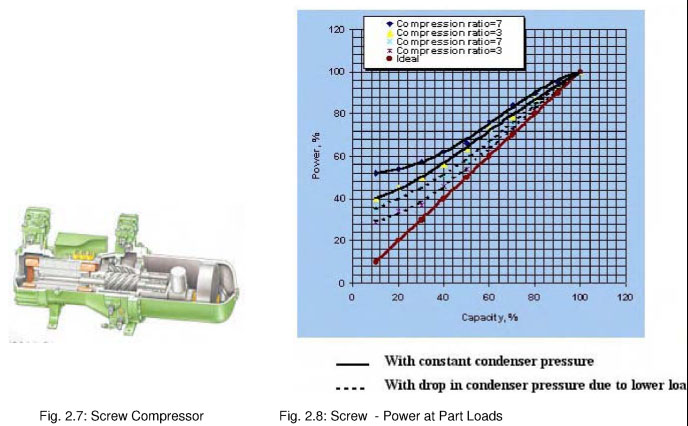

In piston compressor, refrigerant vapour is compressed by the piston in the cylinder (Fig. 2.5). Piston compressors are used usually to one machine, a capacity of 250 TR. . In the case of small cars, the arrangement could be Cycling on/off control on the basis of temperature sensors. However, in larger machines, and frequent starts and stops the engines are not allowed, other methods for controlling power will be taken. In reciprocating compressors with several cylinders, cylinder selectively load or unload on the basis of the set pressure (reflecting temperatures); change of power with cylinder unloading shown in Fig. 2.6.

Unloading implies that the intake valve is permanently open, so that the couple adopted during the suction stroke, returns back through the intake valve itself in the process of discharge of stroke. Piston compressors cannot prevent ingress of liquid refrigerant, which could occur if the evaporator load is less and overheating controlled expansion valve in a position to regulate the flow of refrigerant correctly and excess liquid refrigerant enters the evaporator and gets sucked into the compressor. Ingress of liquid refrigerant can cause severe damage of the compressor.

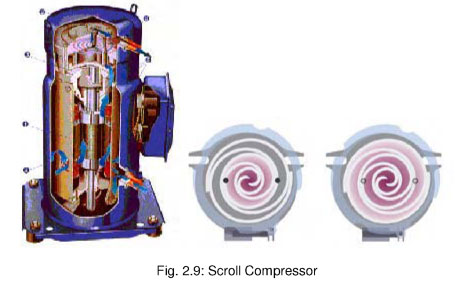

The screw compressor (fig.2.7), there is a rotor with blades and woman rotor with ravines. As the rotors rotating in opposite directions, gas is involved in, receive a sealed between the rotors and the housing shrinks as cavity rests on the end of the body and, finally, as the thread reaches the port of discharge, the compressed gas is supplied to the discharge pipe. Compression ratio in a single stage up to 25:1, much higher than the pressure coefficients of reciprocating compressors. Screw compressors are available for cooling capacities from 10 TR TR 1200, but is widely used in 100-300 TR range. For performance management, control valve is used to get around some of the gas into the suction (depending on the position of the valve), and hence reduce the volumetric efficiency of the compressor. Variations on power and cooling for rotary screw compressor shown in Fig. 2.8. Due to internal power loss control valve below 60% of the capacity is not very effective. Screw compressors can prevent ingress of liquid refrigerant.

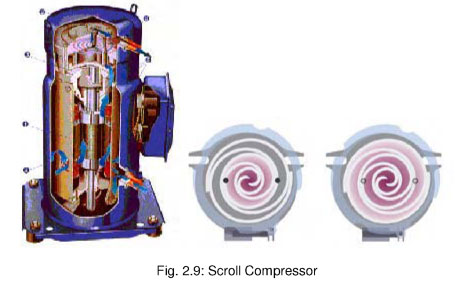

In the scroll compressor (Fig. 2.9); main components of which are two involutive scrolls that implement. The upper scroll that contains a gas discharge port is fixed and the lower scroll orbits. Two scrolls are supported with a fixed ring phase correlation (180) anti-rotation device. As the lower scroll orbits in another form Crescent gas pockets are formed, decreases in volume until they vanish in the center of the scroll key. Suction, compression discharge and simultaneously acted in a constant sequence of orbital motion scrolling. Scroll compressors are available for powers up to 30 TR; multiple compressors are used to build larger packages. Management capacity of scroll compressors is Cycling compressor on and off. Some of the new Scroll design, are able to operate at 100% and 67%. Spiral compressors can tolerate some liquid slugging and particle contamination. Scrolls can tolerate high discharge temperatures and pressures.

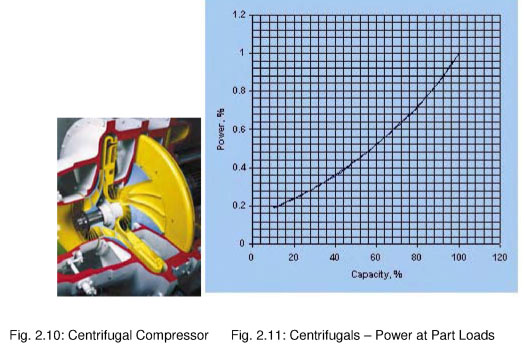

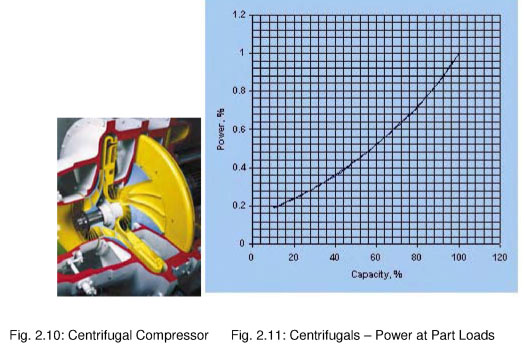

The Centrifugal compressor (Fig. 2.10), large amount of evaporation centrifugal-accelerated high speed and the speed of the energy is converted pressure. Compression ratio is approximately 5:1 at 3600 rpm Speed centrifugal compressor is very high and is about 20 000 R / min, They are made in the range of 35 to 10000 tons. These are used mainly for 150 tons one machine-building. In centrifugal compressors, tanks is monitored at the suction. Performance management in the range 1 0% 1 00%; change of power is shown in Fig. 2.11.

In partial load all of the compressors is inefficient compared with full load, as the authorities have reduced proportionally to the reduction of power. Management capacity for all types of compressors can be made very qualitatively changing the speed of the compressor. In the permitted range of changes in speed will vary depending on the type of compressor and lubrication.

Remember

- There are variations in the efficiency of the compressors of different types and from different manufacturers. Therefore, the precise comparisons are required at the time of selection. Compressor efficiency at part load is a key issue to be addressed.

- It is advisable to avoid using one large compressor, where the cooling load is variable. Several small machines with a working machine that operate at full capacity. more desirable.

..

|