Refrigerated cabinets

Refrigerated cases, the end point of a commercial cold chain, where the consumer purchases the product. The aim is to show produce maximum benefits, having kept it in the established temperature limits. First refrigerator for frozen food was an integral type chest freezer Cabinet ice cream conservative, chest freezer type of Cabinet. Cooling system was built and evaporator consisted of coil pipes in contact with the inner wall. These freezers still widely used for sale of ice cream.

The two main types showcase are those that operate from a remotely located equipment (remote cabinets) and those who work from the cooling system an integral part of the Cabinet (which is sometimes called the plug-in units). Within each of these categories in different types of racks exist. The most frequently used of them : multi-deck; glass doors, well and delicacies. In addition, there are specialized projects for specific products and applications.

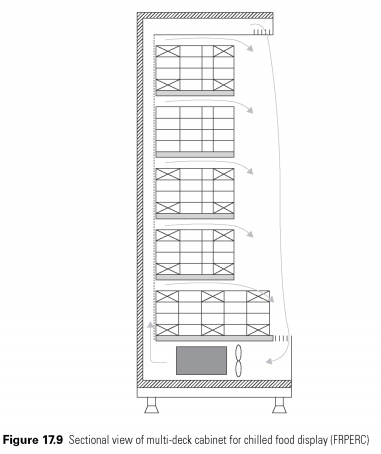

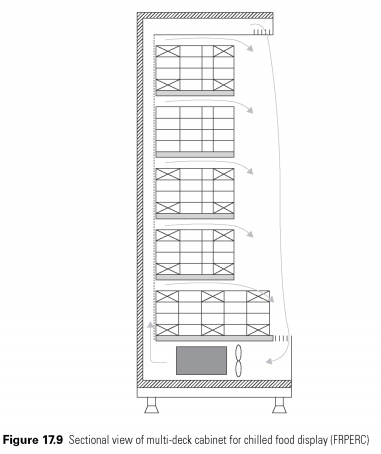

Multi-deck chill cabinets, Fig. 17.9 . rely on the air curtain to maintain the temperature of the products on the shelves.

This type of rack offers an excellent product display, and it is a generally accepted principle that the benefits that can be seen are more likely to be purchased than those that are hidden from view. However, even with careful management of air quality multi-deck cases, as a rule, have a proportionately more heat load than other types. Store managers will facilitate their use, where turnover is rapid.

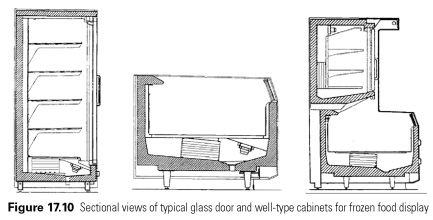

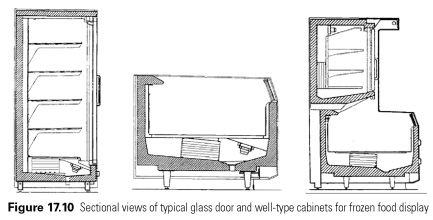

Glass doors, and a well-displays the types, Fig. 17.10. more economical and widely adopted for frozen products. Users agree that there is a need to reduce the loss of energy and a pleasure to shop for frozen products of this type of display. Good lighting and door seal heaters are necessary.

Open-top display may get a significant amount of heat from air infiltration and radiant heat from lighting. Temporary covers frequently used when the building is closed to reduce these achievements and preserving food. This is of great importance where to cut meat displayed because of the radiant heat from the light and the loss of cold air blanket lead to loss of moisture from the surface of the heavy dark appearance. It helps to have glass walls on the sides to reduce the pieces that would disturb the layer of cold air into the Cabinet. Evaporator coils can be outside of the inner wall or finned coils on the back or on the sides. It is important that the products are kept below the level of the design of cold air blanket. An integral reach-in displays are used for various products and specialist designs on request for small retailers, hotels and restaurants, Fig. 17.11.

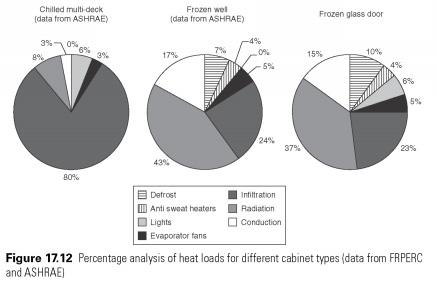

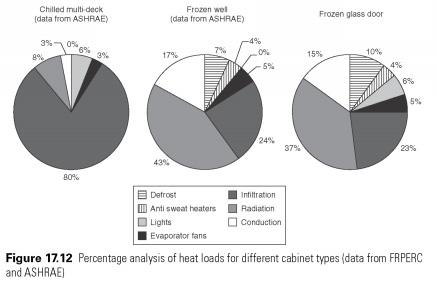

Evaporators should be thawed at regular intervals, usually every 6-8 hours. Increase of frost on the evaporators may be limited air conditioning plot and thus reduce the amount of moisture in the air. Energy consumption cabinets determined in accordance with standard methods, which take into account both direct input power to the Cabinet for lighting, fans, heating and defrosting heaters and power consumption required for heat dissipation. Testing revealed significant differences in consumption, and 15-20% of energy savings can be achieved by many users at the choice of the efficient products (Evans et al., 2007). The heat load analysis on different types of chassis, shown in Fig. 17.12.

.. ..

|

..

..