Pipelines for oil return

Change the size and location of the suction and pressure lines for halocarbons obliged to ensure proper oil carry-over to give back to the compressor. Pipes for gas usually have higher speed at the expense of greater pressure drop than those for ammonia. The pipe dimensions can be increased only works where the oil will flow by gravity in the same direction as gas.

Horizontal tubes should hill above the direction of flow, where this can be arranged. If the line suction or discharge growth, the size can be reduced from the gas to move faster. In case of lifting more than 5 m, the trap should be formed in the lower part to collect oil, which falls ago, when the plant was stopped.

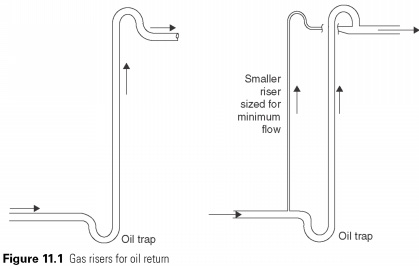

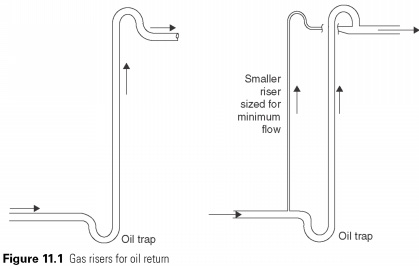

Suction and discharge struts (Fig. 11.1), as a rule, large size, the full capacity of the compressor, and velocity is too low, if the loss of capacity for work. In such facilities, double, risers, which require less to take the minimum power, and the two together to bear in full swing. Trap at the bottom and goosenecks at the top of the full agreement. In the part of the vessel, any oil that is not executed until the main riser will recede and eventually block trap at the bottom, leaving fewer pipes carry the reduced flow, its quota of oil. When the system switches back to full power, the party of oil into this trap will be blown clear again.

....

|