Refrigerants

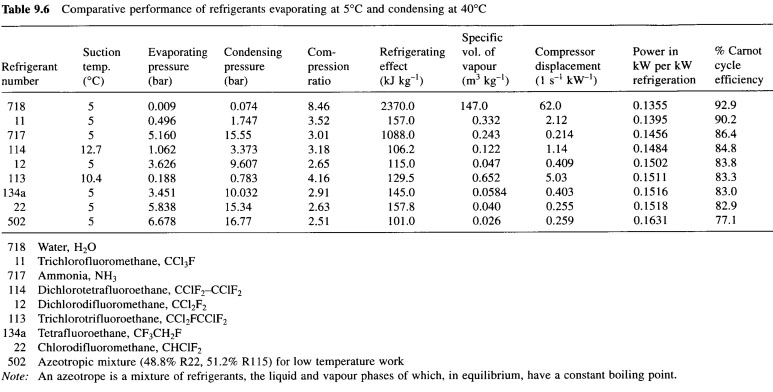

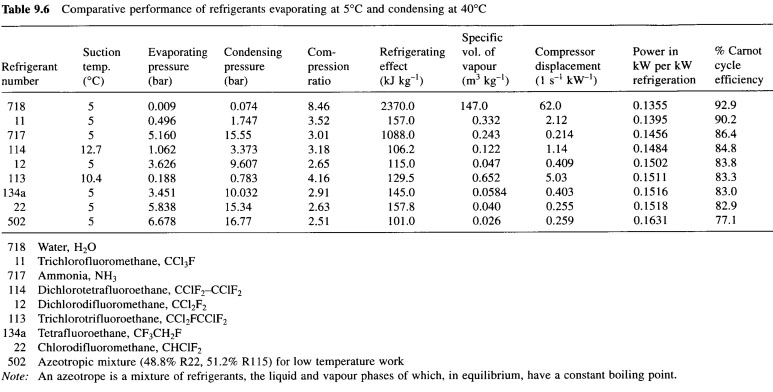

Comparative indicators of commonly used in vapour compression cycle shown in the Table. 9.6 whose values were calculated using the methods in this Chapter. Actual operating conditions, therefore, will be somewhat different due to the impact of the factors mentioned in paragraph 9.2.

In General, it is assumed that the pair is in compressor in the saturated state on 5C. In refrigerants 113 and 114, however, where the saturated suction gas can cause condensation during compression, enough overheating was taken to ensure saturated discharge gas. Is the overheating was not counted as part of the refrigeration effect.

Condensation temperature of 40C were adopted for all refrigerants. Speeches were calculated on the assumption that the isentropic compression. A number of factors must be taken into account when thermodynamic characteristics listed in table assessment.

For example, if the working pressure is high, then the materials comprising the cooling system will be heavy, and оборудование expensive. Refrigerant containers will also be heavy, and this will increase the cost of transportation. Sub-atmospheric pressure, on the other hand, means that any leakage due to air entering the system.

In reciprocating compressors, volume (liter s_1 kW-1) should be low, so that the required performance can be achieved with a small machine. For centrifugal compressor on the other hand, large displacement is desirable to allow the use of large flues. Reduction of friction resistance in such passages increases the efficiency of the compressor. The power required to drive the compressor, obviously, is very important because it affects the production costs and the cost of refrigeration applications. Although not specified in the table, critical and negative temperature of the substance also be borne in mind when assessing its suitability for use as a refrigerant.

Of course, there are other factors besides thermodynamic that should be taken into account when selecting a refrigerant for specific vapor compression cycle. They include heat transfer characteristics, dielectric strength vapor, Flammability, toxicity, and chemical reactions with metals, memory leaks and leak detection, behavior in contact with oil, accessible and of course, cost.

In General concern about the ozone layer and the effects of global warming refrigerants, widely used stimulated the search for alternative, more acceptable refrigerants. Among those are: established refrigerants such as ammonia (provided the proper safety measures are adopted), hydrocarbons (providing safety precautions), and a mixture of two or more refrigerants that are unusual effects and incompatible with traditional mineral oil for lubrication of the compressor.

Butler (1998) discussed the mixture of the refrigerant with components that boil at different temperatures, giving changes in boiling (called " slide") in the form of a mixture evaporated or condensed. Bubble point is the temperature at which the liquid refrigerant-only begins to evaporate and " dew point is the temperature at which the vapor starts to condense. With one refrigerant these points match and AZEOTROPIC mixture having liquid and vapour phases in equilibrium also has a constant temperature of boiling. On the other hand, for the isotropic mixture of, constituents have different boiling points and the difference is called glide value for the mix.

Glide can lead to drop of temperature glaze through evaporator and condensers and evaporators, as a rule, more than one of the refrigerant. Changes in heat transfer characteristics and the refrigerant handling there are difficulties with the glide. Please note that the refrigerant and the lubricant is a zeotropic mixture requires a special consideration. Whereas, hydrocarbon refrigerants are compatible with conventional mineral oils, HFC refrigerants (such as R134a) and their mixtures and not polyester lubrication is required...

|