SYSTEM PEAK THERMAL LOAD AND LOAD PROFILE

One main purpose of the work hmm-for the production of chilled water as economically as possible. To reach this goal, not only of individual chillers be effective, but the entire system must be designed to function effectively.

The first step in determining the requirements for the cooling water system for determining the peak load of the cooling requirement. However, the peak load will occur only for a very limited number of hours during the year. On an annual basis, the load will vary depending on the time of day due to the placement of structures, solar heating, and daily temperature drops, etc. and time of year due to solar and seasonal variations in temperature. Another factor that affect the load on the chilled water plant is the number of core area of the building, which requires refrigeration year-round and will airside economizer cycle installed to provide free cooling in winter. All of these variables, each of the cooling water system will run much more hours at partial load, than it will work on the peak load.

Thus, in addition to determining the maximum load imposed on the system, it is necessary to determine the part-load profile, or as a function of time, air temperature, or both.

The best way to illustrate the process of evaluation of the cooling system load profile for example:

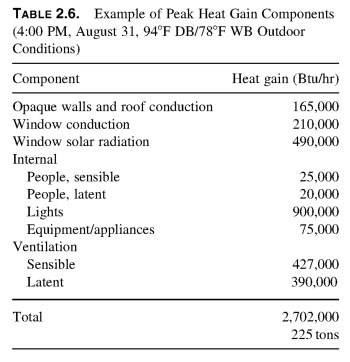

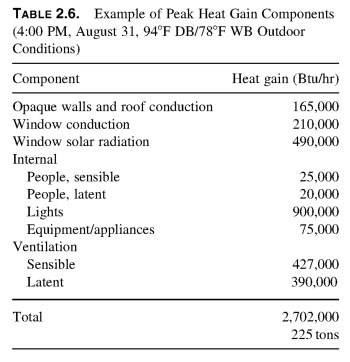

- Suppose a chilled water system serves a building with peak-load characteristics are given in Table 2.6. This is the peak load on the basis of the building is used entirely at 4:00 on August afternoon.

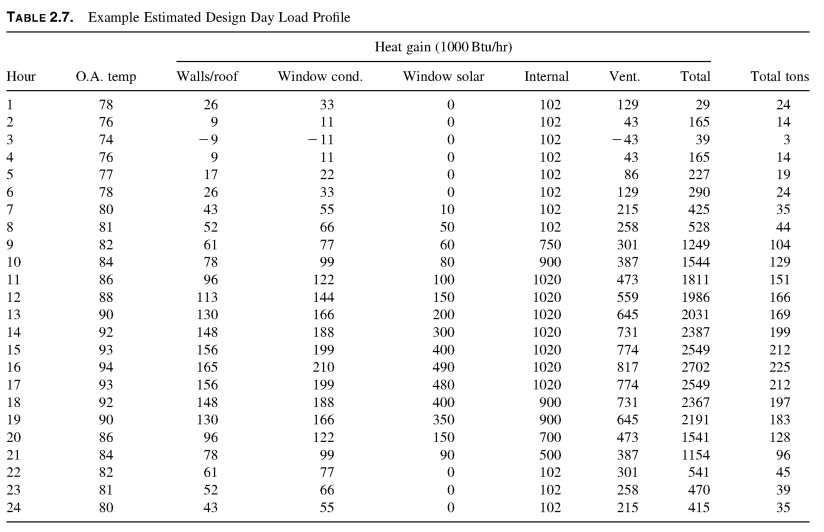

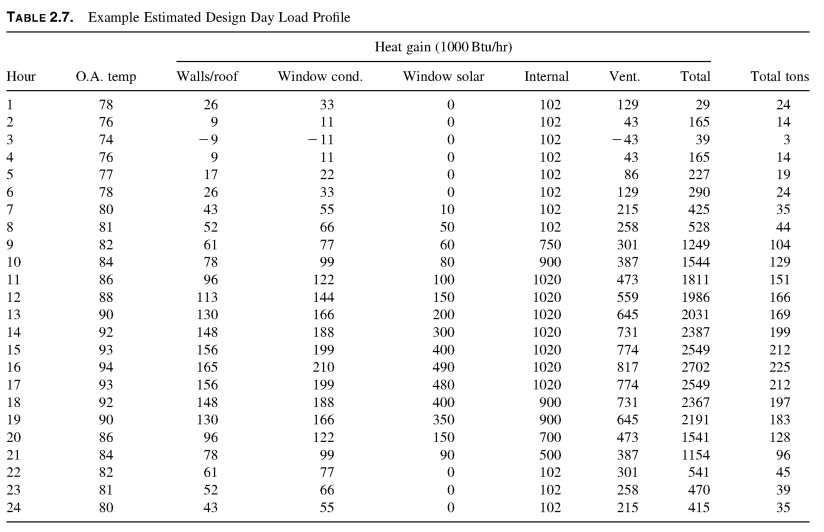

- The next step is to estimate the peak day of load profile by determining the load every hour of design day, as shown in the Table. 2.7. Please note that there is accommodation variable for lighting and other internal heat gains, solar variable due to the cycle of day and night, and variable temperature due to diurnal temperature profile for a 24 hour period.

3. Next, check the load with winter outdoor conditions. While the capacity of the variables are the same as for the summer months, sun and temperature variables will differ markedly. To determine imposed chilled water load, the building can be considered the perimeter of the zone in which the heat loss through the walls, roofs and Windows of the displacement of the internal heating and core zone, in which only the roof loads can be considered displacement of the internal heating. Obviously, the cold air ventilation can help to offset any imposed space cooling system.

In Table 2.8, building it is assumed that 50/50 core/perimeter of the square relations and goods being checked at various temperatures of external air for both occupied and unemployed conditions.

4. Finally, consider the impact of air economizer cycles. If all the air-handling units are equipped with economizers, there are no requirements for water cooled to temperatures below cooling coil discharge temperature, usually 50-55F. If the airside economizers is not provided, then either chilled water should be ensured through implementation of the chillers and/or with the use of the coastal economizer cycle (see C. 14.2).

From this evaluation, as the peak load and minimum burden imposed on the chilled water system are determined.

- In this example, the peak load 225 tons.

- If the example of the building were of an office building, in all probability, air system will shut down when the cleaning crew completed at approximately 8:00 (hour 20) not begin until about 6:00 (6 hour). However, the lab building, air-conditioning system will operate 24 hours a day. Thus, from Table 2.7, a minimum load on the chilled water system may be only 3 tons if the building were cooled 24 hour security, 24 tonnes if the building was closed for the night.

- Based on the data in Table 2.8, the building will require cooling water cooled during the occupied period up to 40F temperature of external air. If airside economizers, the minimum winter occupied cooling load is 76 thousand tons occurring at 60F temperature of external air.

..

|