High-Efficiency Furnace Electrical Controls

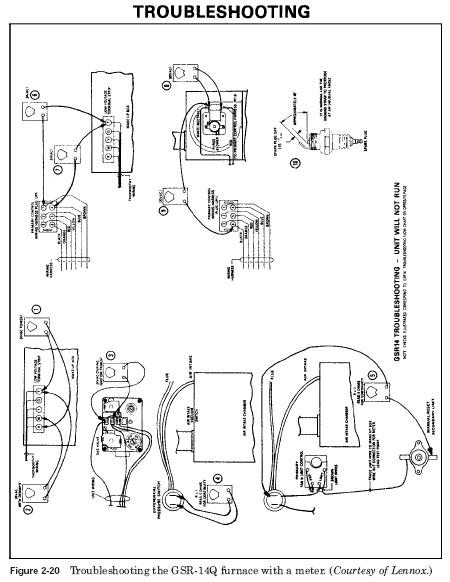

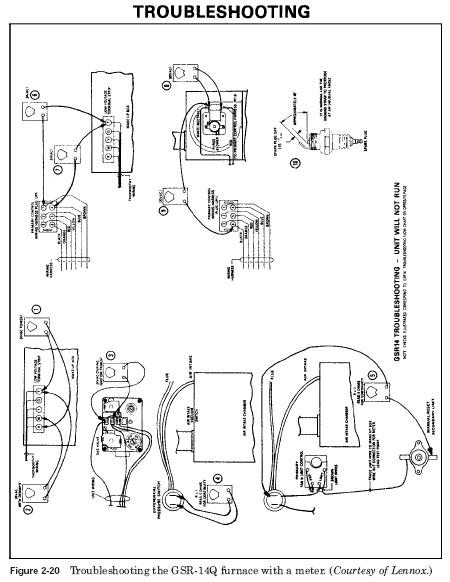

The oven is equipped with a standard type redundant gas valve in series with a gas expansion tank, gas consumption flapper valves, air intake flapper valve. Also the factory setting cleaning, blowers, spark ignition, flame sensor ignition with solid-state control Board. Standard equipment includes fan and control of limits, 30-VA transformer cooling fan relay, flexible gas line connector, and four areas for the installation of insulation, as well as a base insulation pad, condensate leg, and the cleaned air filter. Chimney/hood line, roof or wall termination mounting kits, LPG conversion kits, and the thermostat are available as accessories and must be ordered extra, or you can use an existing when the unit is replaced. PCB is replaceable unit when there is a malfunction in one of the components. He uses multivibrator transistorized circuit to generate the high voltage required for ignition. Spark gets very little use except to start the process of combustion. He has a long service life. Spark gap 0.115. and grounding electrode is adjusted to 45 (see Fig. 2-20).

..

|