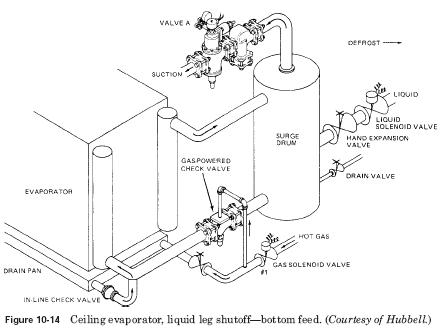

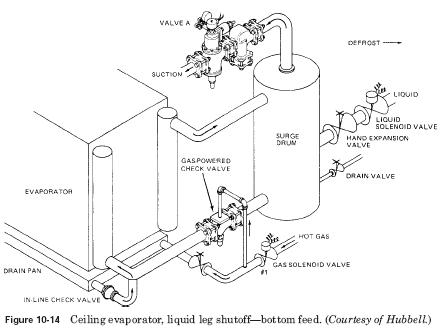

Flooded-ceiling evaporator liquid leg stop

The bottom of the hot gas feed Fig. 10-14 illustrates flooded-the ceiling of the evaporator. After enabling the startup sequence, the hot gas solenoid (no 1) was opened. The supply of gas to the gas non-return valve, isolating the bottom of the expansion tank evaporator. Hot gas flows through the pan coil and in line check valve evaporator. Excess gas pressure is dumped into the expansion tank. It will bleed through the valve A. During defrost, this valve is de-energized to perform as a relief to the regulator about 70 pounds per square inch.

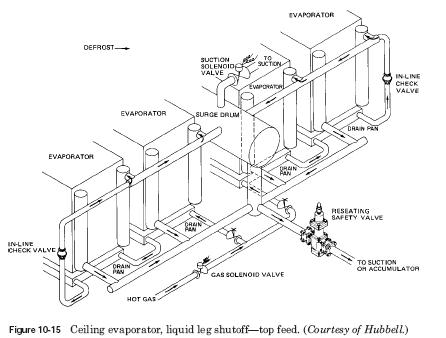

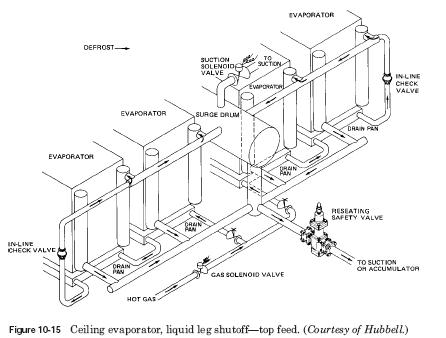

Top hot gas feed Fig. 10-15 shows a few of the flooded evaporator with system of input and output header for connection to various evaporators and separator. Please note that after defrost, liquids and condensate is removed from the evaporator and a surge in the remote battery through the regulator, which is the safety valve is closed.

Usually it makes about 70 pounds per square inch. The battery must be sized to take refrigerant, plus hot gas condensate.

..

|