Materials and pipelines Insulation Requirements

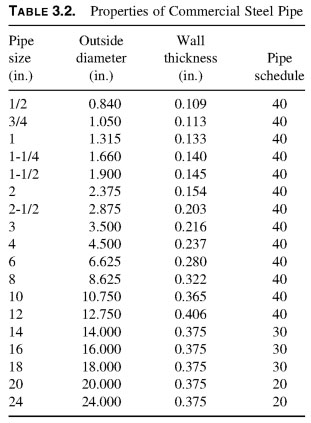

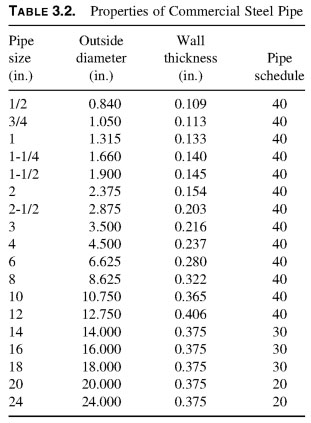

Chilled water distribution systems assembled from commercially available piping materials, most often of steel and copper. Steel PipeThis is the most common aboveground piping type and thickness of the wall, called a graph, and its finish. Through the 12th century, the pipe size, Schedule 40 pipelines, as a rule, is used for chilled (condenser) water applications. For pipelines of the 14th century and more, the majority of designers standardize pipelines, 0.375. wall thickness, and ignore pipe schedules. All cooling water pipes made of pipelines, mill finish and is called black. Pipelines of the 2nd century and is typically less than the collected threaded connections, while the pipeline 2-1/2 century and more, as a rule, assembled by welding. In table. 3.2 lists the physical properties of the steel pipe is widely used in water systems.The fittings, of steel tubes with screw connections are typically built of cast iron is rated for up to 125psig working pressure. Forged steel buttwelding fittings are used for welded pipes.

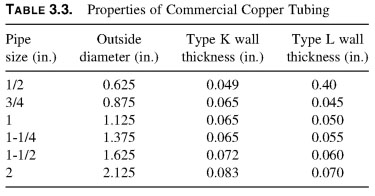

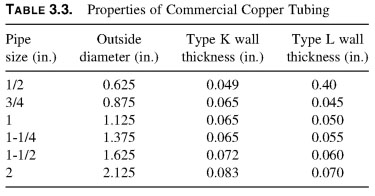

Copper Pipescost of copper pipes higher than that of steel pipes, installation, the cost of labor smaller size, 2 C.

and less, much less, than steel. Thus, the majority of designers allow copper pipes are used in water supply systems for these smaller sizes contractors option.To prevent galvanic corrosion initiated dissimilar metals in direct contact, the relationship between the steel and copper pipes materials must be electrically separated by a dielectric Union. This valve uses rubber gaskets to separate the two materials.The wall thickness of copper pipes indicates its type, defined as the Types K, L and M in order to reduce the wall thickness (Table. 3.3). As a rule, Type K or L tubing can be used for pipeline of the cooled water, but the Type M, the wall thickness is too thin.Fittings for copper tubes are wrought copper and tubes and fittings are mounted with the help brazing.

Cast or Ductile ironFor laying underground pipes, cast-iron pipes or pipes ductile iron to use in everyday work. Iron pipeline is designed to operate in conditions of pressure class and for most systems of water cooling Class 350 is used through the 12th century, the pipe size, Class 250 per 14-20. pipes, and Class 150 for pipelines 24 century and larger.Fittings cast of grey or ductile iron fittings and pipelines are installed with gasketed mechanical pressure on the joints.

PVC and CPVCalternatively iron for underground pipelines chilled water distribution, PVC and CPVC piping can be used. PVC and CPVC pipeline wall thickness determined in accordance with schedules, like the steel pipe. For chilled water applications, Schedule 40 pipelines, as a rule, used.Fittings are also formed from PVC and CPVC and joined solvent soldering through 4. pipe size and folding mechanical pressure on the joints for large sizes.

All above-ground pipelines should be insulated to reduce unwanted heating of the surface and prevent condensation with chilled water temperature, usually below the dew point of the surrounding air temperature during the cooling season. And as little as 1. isolation can serve as a limitation of heat flow (and, to meet current energy codes), more insulation may be necessary, especially in the southern climates to prevent condensation on the surface. Thus, at least the 2nd century insulation is recommended.

Because on the surface of the pipe cold, isolation must be applied before the chilled water system in operation to ensure a dry surface for the application. Then, the insulation must be completed with the outer shell, which includes a vapour barrier to prevent the migration of moisture through the insulation and internal condensation. The most common vapour barrier consists of a Kraft paper and aluminum foil laminate, fiberglass reinforced streams (called foil, closed and Kraft or FSK). Preformed glass fiber insulation with a factory-all French will include a vapour barrier is required.

.. ..

|

..

..