The Drive Motor Is Chillers

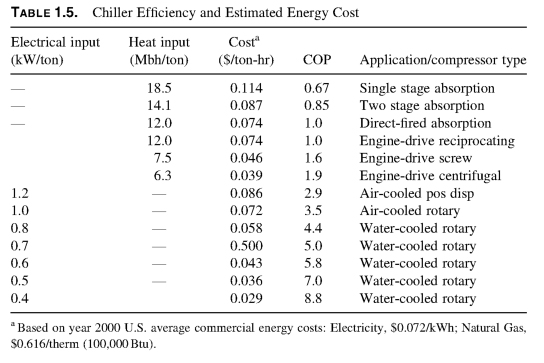

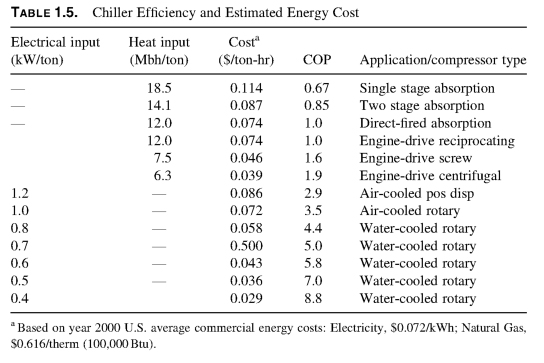

Natural gas and propane fueled by spark ignition engines were applied to rotary compressor systems. Full-load efficiency of the coolings for engine coolers approximately 1.0 for reciprocating compressors, 1.3-1.9 for screw compressors, and 1.9 for centrifugal compressors. These low COPs can be improved, if the engine is cooled by water and heat exhaust heat can be recovered for heating of service hot water or for other purposes.

The drive motor is chillers have been around for many years, but their application, as a rule, most often using natural gas as fuel, was limited to a number of factors:

- Above cost.

- Air quality regulations.

- Much higher maintenance requirements.

- Short engine life.

- The noise.

- Greater physical size.

- The lack of integration between the engine and cooling subsystems.

Since the mid-1980s, manufacturers have made efforts to reduce the negatives with a more compact design, emission control system, noise abatement measures, the main engine improvements, and overall level of development of management systems with the use of microprocessors.

However, the requirements to the maintenance of the engine, drive chillers remains high, adding about $0.02/tonhr to the chiller operating costs.

Currently engines of a kind used for chillers, or with spark-ignition automobile engines based blocks, heads, and any moving parts (below about 400 tons), or with spark-ignition engines and diesel-blocks and move the components (for large chillers. While in the automotive industry, derivative engines have advertised 20.000 hr useful life, the real life can be much shorter, requiring replacement of the engine every 2 years or so. Diesel-derived engines require major repairs every 10-12,000 hr (equivalent diesel truck traveling 500,000 km, 50 miles per hour).

New engines using a lean burn technology to improve combustion and reduce CO and NOX. Adding catalytic converters and exhaust system, and additional emissions controls, natural gas-powered engine chillers can meet the stringent California air quality regulations.

Gas engine-disk chillers remain more expensive than electric drive units and they have higher General operating expenses, including maintenance costs, (see Table. 1.5). However, the motor-drive chillers can be used during peak cooling times of falling seasonal peak electrical load charges (see 2.3 Sec).

.. ..

|

..

..