Refrigerating core installation. Capacitor

The purpose of the capacitor delete amount of heat equal to the amount of heat absorbed by the evaporator and the heat produced by compression. There are many different types of capacitor. Shell-and-tube condenser. This type of capacitor is used in applications where there is enough water for cooling. It consists of a horizontal cylinder with welded flat caps, which support the cooling tubes. End covers are fastened to the end of the album.

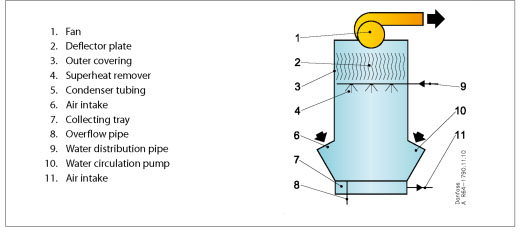

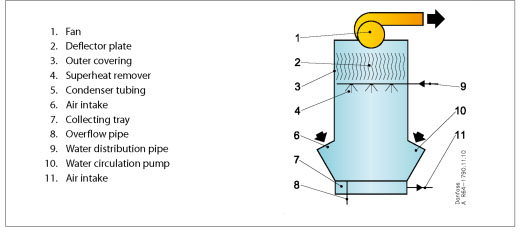

Refrigerant condensate flows through the cylinder, cooling water through the tube. End covers are divided into sections in the ribs. Sections of the act as reversing cameras for the water so that it circulates several times through the condenser. As a rule, water is heated 5-10 C, when he passed through the condenser. If desirable or even necessary to reduce the amount of water evaporated capacitor can be used instead. This type of capacitor consists of body, where there is a condensation coils, water distribution pipes, metal sheets and fans.

Warm vaporous this led to the beginning of the condensing coil, after which it is condensed and is working from the bottom of the coil as a liquid.

Water distribution pipes with nozzles located above the condensing coil so that water is allocated and running down the coil. Supporters direct, a strong flow of air through the heat exchanger of the condenser heat exchanger. When falling water drops satisfy the ascending air flow of water will evaporate. It absorbs the necessary boiling heat from the refrigerant and accumulated.

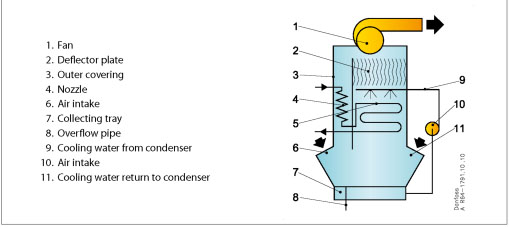

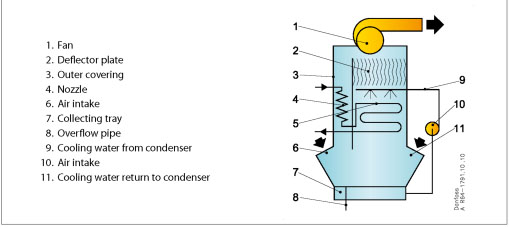

The main participation of the evaporation of water is also used in connection with the use of cooling towers. They are established, when it is most expedient to place the shell-and-tube condenser near a compressor. The water is then distributed in the chain between the condenser and cooling towers.

In principle, the tower, built same as boiling capacitor, but instead of condensing elements of a deflector plate. Air is heated on its way through the tower by direct contact with the trickle of water travel down and, therefore, are able to absorb more moisture coming from the part of evaporation. Thus, cooling water loses heat. Water losses constitute delivery of additional water.

You can save 90-95% of the consumption of water by evaporation condensers and cooling towers in comparison with the consumption of water from shell and tube condensers. For various reasons this is not always possible to use the water for the condensation process. In such cases, an air-cooled condenser should be used. Because the air poor heat transfer characteristics, as compared with the water, a large outside surface of condenser tubes you need. This is achieved by large ribs or fins, and, in addition, the generous provision of air circulation mechanically.

This is the normal capacitor refrigeration unit...

|