Thermostatic valves

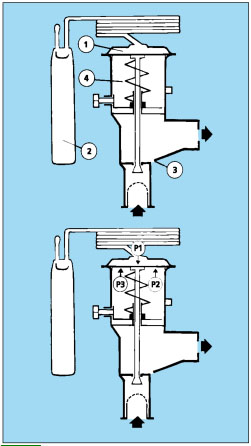

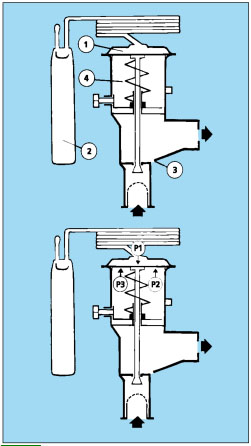

Thermostatic expansion valve, built around a thermostatic element (1), separated from the valve body by using a diaphragm. Capillary tube connects element lamp (2) and valve body, valve (3) and spring (4). Function thermostatic expansion valve is determined by three main pressure:

- P1: Lamp pressure that acts on the top surface of the membrane, in the direction of the valve opening.

- P2: Boiling pressure that acts on the bottom of the diaphragm, closing the valve.

- P3: Spring pressure, which also operates in the lower part of the aperture in the direction of the valve.

When the expansion valve adjusts the balance between the pressure light on one side of the diaphragm and evaporating pressure plus the spring force on the other side. Spring is used to configure overheating.

Overheating

Overheating is measured at the point where the ball is in the suction line and the difference between the temperature of the lamp and pressure boiling point/boiling point at one point.

Overheating is measured in Kelvins (K) and is used as a signal to regulate the injection of the liquid through the expansion valve.

Hypothermia

Hypothermia is determined as the difference between the condensing temperature/pressure and temperature of the fluid in the expansion valve at the inlet. Hypothermia is measured in Kelvins (K). Refrigerant sub-cooling is necessary to avoid air bubbles in the refrigerant ahead of the expansion valve. The refrigerant vapour bubbles reduce the capacity of the expansion valve, and thereby reduce the supply of liquid in the evaporator. Hypothermia 4-5K is suitable in most cases.

Expansion valves with external pressure should be always used if the liquid distributors are installed. As a rule, the use of distributors gives a pressure drop of 1 bar through the distributor and distribution pipes. Expansion valves with external pressure should be always used in refrigeration systems with heavy evaporators or plate heat exchangers, where, as a rule, the pressure drop will be greater than the pressure corresponding to 2K.

Thermostatic valves can contain one of three different types:free of charge :

- Universal charging

- MOP free

- MOP charge with ballast, standard for expansion valves with Danfoss SS.

expansion valves with Universal charge used in the majority of refrigeration systems, where there is no limit pressure requirement and where the lamps can be located warmer than the element or high temperature boiling point/boiling pressure.

A universal payment means that there is a liquid charge in the ball. Board size is so large that the charge remains in the ball, regardless of whether the item is colder or warmer than incandescent bulbs. Expansion valves with SS fee is normally used on factory units, where suction pressure restriction on run, if necessary, for example. in the transport sector and in air conditioning systems.

All expansion valves with SS have a very small fee into a ball. This means that the valve or member must be warmer than incandescent bulbs. If not, are free to migrate from the lamp to the element and prevent the expansion valve normally. MOP fee means limited liquid charge in the ball. MOP" means the Maximum Working Pressure is the highest suction pressure boiling valid evaporator pressure/suction line.

Charge vanished, when the temperature reaches MOP point. Gradually, as the suction pressure rises, the expansion valve begins to close by approx. 0.3/0.4 bar below the SS point. He becomes completely closed, when the suction pressure is the same as the MOP point. MOP is often called Motor Overload Protection".

Expansion valves with SS ballast fees, which are mostly used in cooling systems high dynamic" evaporators, Рµ.Рі. in air conditioning systems and tube heat exchangers with high heat emission. With MOP ballast charge, up to 2 - 4 K less overheating can be obtained in comparison with other kinds of charge.

A lamp in TRV contains a material with high porosity and a large surface area is in relation to the mass. MOP charge with ballast provides a soothing effect on the expansion valve regulation. The valve opens slowly, as the thermometer rises and closes quickly, as the thermometer fails...

|