Expansion Valves

Extension devices are devices that control the refrigerant flow to match the flow of the refrigerant with a boil rate in the evaporator, in the process of reduction of the refrigerant pressure / high condensing pressure low pressure in the evaporator. Use the coil is more effectively liquid refrigerant must be present until the end of the coil, instead of providing some areas of the end section of the coil for overheating of the refrigerant. However, overheating section is a compromise to protect the compressor from the possibility of the fluid entering the compressor.

High pressure liquid refrigerant passes through the expansion unit into the evaporator, where the refrigerant evaporates due to the heat from the fluid or material is cooled. Expansion device can be fixed diaphragm or capillary tube, manually controlled valves, thermostatic, electronic or balanced port valve, float valve or overheating controlled expansion valve.

Orifice plates and capillary tubes are used only for smaller machines, window air conditioners, refrigerators and other where capacity control compressor Cycling on and off, and no flow control refrigerant required.

Thermostatic valves have holes, to ensure that the pressure drop and a needle valve and aperture to regulate the flow with the use of refrigerant from the evaporator refrigerant vapour temperature, which is around 5K above the boiling point, to prevent fluid inside the compressor.

Balanced port valves similar to thermostatic valves, in addition to special internal balanced port design that help improve the flow control.

Electronic valves are also similar to thermostatic valves, with the difference that the temperature felt in electronic form, and hole changed or the heated fluid pressure or electric valve actuator.

Electronic valves can be easily integrated into an electronic microprocessor-based control system.

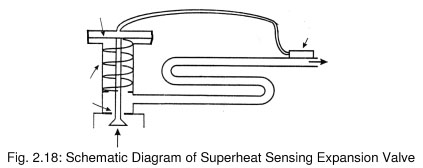

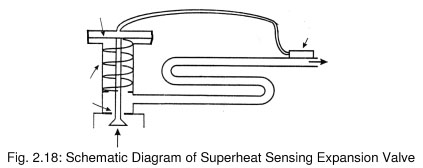

Overheat sensing valve (Fig. 2.18) is the most widely used refrigerant flow control device. This valve controls the superheat of refrigerant vapour at the outlet of the evaporator. The valve is positioned pressure difference on different sides of the membrane. Pressure under the diaphragm is provided by the refrigerant entering the evaporator and the pressure on the upper side of the diaphragm through the power of the fluid, which is the same refrigerant in the system. Minor force exerted by the spring on the valve keeps the valve closed until the pressure above the diaphragm overcomes the United forces in the spring and pressure in the evaporator. For pressure above the diaphragm to be higher than the pressure in the evaporator below the diaphragm, power, temperature of the pumped liquid should be above the saturation temperature in the evaporator. The gaseous refrigerant from the evaporator, therefore, should be superheated deliver energy of the liquid to the valve opening pressure.

Work overheating controlled expansion valve can be sluggish at partial load, i.e. when the compression ratio is low. Electronic expansion valve which can operate at very low overheating parameters allows more than the length of the coil be used for liquid refrigerant compared to traditional expansion valve, and thus improves the coil performance. Roman expansion valve controller developed in India in the sense of the process temperature and the heat or cool the sensing bulb quicker to work overheat sensing expansion valve more sensitive at partial loads. The use of these devices allowed to improve accuracy and temperature stability and energy saving.

Float valves are used in systems where flooded liquid refrigerant level in the equalizing perceived and supported. In addition, manually adjust the valves level switches are also flooded evaporators...

|