Sizing & Selection of the proper Refrigeration Machine

Assess the availability of energy on the spot, i.e. electricity, cheap heat source or heat. Energy economy for the Vapour Compression System or Vapor Absorption System or a Hybrid System will be made in the cooling load profile and the cost of energy.

For very low temperatures of the evaporator temperatures below -20C, in a two-phase vapour compression systems with inter-cooling must be taken to limit the discharge pressure. For evaporator temperatures below -50C, cascade systems can be considered. If a cheap source of heat or waste heat opportunity to use a Water-ammonia Absorption chillers, also does not exist.

Avoid exceeding the sizes, to the extent possible, try to match the actual load, provide efficient modulation method. The use of large chillers will increase parasitic loads, such as pumps, fans and other Dimensions and the number of refrigeration units must be selected to match the load profile as closely as possible; the same applies to the parasitic loads, such as pumps, fans and other It may even involve the choice of uneven size of the machine.

Water cooled machines are usually preferred for refrigeration systems.

In the case of water shortage, a lack of water treatment facilities, non-availability of space for cooling towers etc. solution strength.

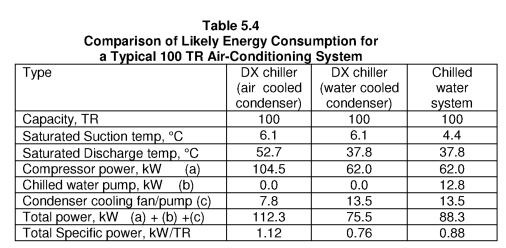

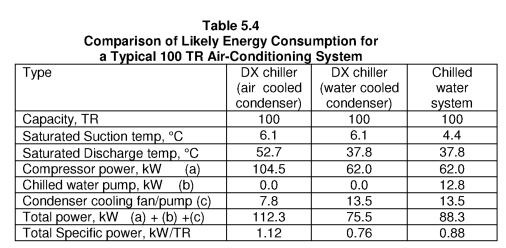

In the case of air conditioning systems, type systems can have a significant impact on energy consumption. Air can be cooled by refrigerant directly in AHU cooling coil (DX-type chiller) or chilled water in the AHU the cooling coil. Table 5.4 shows a comparison is likely to energy consumption for a typical 100 TR-conditioning system with different types of systems. DX-chiller water cooled condenser is the most effective.

Selection of equipment for the vapour compression systems should be made that most of the working equipment will operate near their full load and near their best operating efficiency indicates the estimated plant cooling load at different points in time. It must also be ensured that the associated equipment such as pumps, fans and other also sized to ensure reduce energy use and cut parasitic load system. Select the cooling coils for high temperature drops at design conditions to reduce energy pumping.

When comparing the efficiency of different refrigeration efficiency should be compared with full load and part load. Buying decision should be based on the most probable load that is likely to prevail for a long period of time.

In applications where size is inevitable, consider the use of variable speed drives of pumps and compressors.

In case of Absorption Chillers, since the ability to control up to 25% can be done without loss of efficiency, one hmm configuration can be resolved. However, variable speed drives can be set to optimize the flow pumps depending on the load.

Nott large refrigeration plants unnecessarily, it may cost more to buy and run!

Buying only the high performance machines, even at a premium. The use of large heat exchange surfaces of evaporators and condensers. Consider realistic fouling factors based on water quality and General of the nearest environment. It should be noted that energy-efficient cooling systems always work with a smaller temperature lifts (or compression), which leads to lower discharge temperature and the resultant benefits from reduced energy consumption, reduced maintenance costs and increased reliability.

Equipment manufacturers may be too optimistic about the performance. In the Indian context, the marketing personnel to exaggerate the positive traits and underestimated or hide negative characteristics of the equipment. Information provided by manufacturers should be checked and verified by independent, reliable sources. ASHRAE and ISHRAE some directories from reliable sources

Standard cooling packages may not be the most optimal configuration. It is always advisable to configure the package for the improvement of the COP. In most cases, this means providing more area of heat transfer in the evaporator and condenser, to raise or lower the temperature (compression ratio). Expansion device should be ideally electronic valve or port valve, instead of the usual overheating sensing valve. In the case of normal overheating valve is used and partial load of the refrigeration machine, most likely, modernization of the precision of the temperature controller can be considered.

Cooling tower capacity is much cheaper than chiller capacity. Big tower will provide cool water to the chiller at a very low price, and thus enhance their efficiency in the "off-design conditions. Two-speed electric motor systems offer almost all the advantages of variable speed drives for fans of the cooling tower at significantly lower costs.

Select refrigerant taking into account the depletion of the Ozone layer, the problem of long term availability, operating temperature and pressure conditions, the type of compressor and security. Consider zeotropic mixtures, which can give advantages as increased evaporator performance and efficiency. Zeotropic mixtures are more suitable for DX system, contact your supplier before using them in flooded systems.

In case of absorption chillers, the user has no choice, the car will be sold as a package.

Using energy efficient motors for continuous or almost continuous operation of the application should be preferred...

|