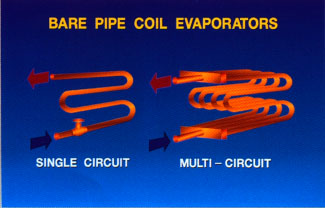

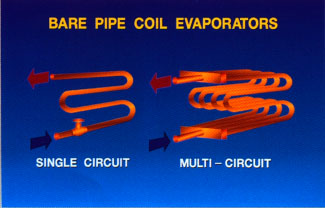

Naked Tube

Here you can see two types naked tube or bare-tube evaporators. Everyone just steel or copper pipes, the form, in a manner that best fits the piece of work. Bare-tube evaporators, also called "the Prime surface coil, because their primary surface of the pipe, this is only the surface, used to transfer heat.

Coil, left, has one circuit, and the right multi-circuit. Several circuit design is the rule, because it saves space and simplifies the mounting of pipelines for the coil(s), and reduces the number of devices of the account of the need.

Bare-tube evaporators work well as a D-X and flooded evaporators. They are most often used in refrigerating work where space temperature is below 34F. In such applications, saturated temperature of the refrigerant in the evaporator below 28F, which is the approximate temperature that will turn condensation on the surface of the evaporator in the frost. In these applications, frost builds on a spool; however, a little-pipe design effectively works even with frost accumulation.

It is also easy to clean and thawed. These coils are often immersed in liquid cooling or freezing tanks.

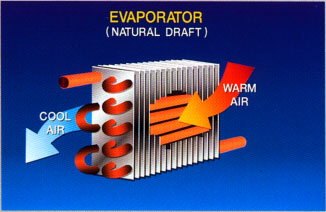

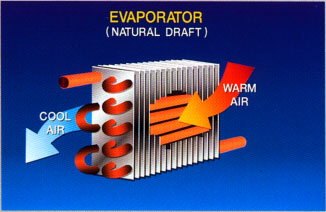

In natural draught, evaporator, air circulation, caused by differences in the mass of cold air and warm air. As the air comes in contact with the evaporator tubes, it cools, it becomes more dense and begins to fall. Warm air, then moves in to fill the area around the evaporator. This is a fairly slow process, and limits the ability of the evaporator absorb heat in a short period of time.

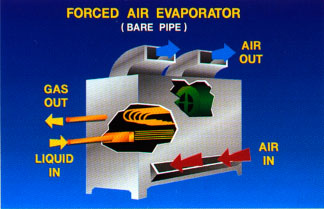

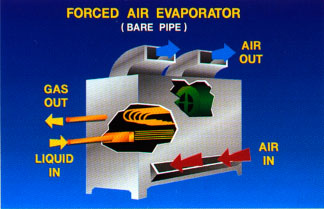

This image shows a bare-tube evaporator installed in the unit. Quick movement of air increases the capacity of the coil, bringing more air in contact with the cooling surface in a short period of time.

This type of evaporator is particularly applicable for Coldroom in which the temperature is below zero and high air velocities is not harmful. This device can use the D-X or flooded refrigerant supply, depending on its application. Both screw and centrifugal fan models with forced draught, with bare-tube evaporators. Some are mounted on the ceiling. Circulating brine can be sprayed onto the coil to increase cooling capacity and remove frost on some models.

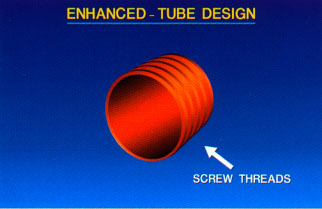

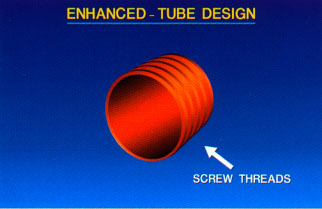

Various methods have been developed to increase the efficiency of bare-tube evaporators, increasing the volume, surface area, which is in contact with the coolant. Chase along along the inside or the outside of the tube is one of such ways. Another method uses a spiral groove, which is reminiscent of a screw thread on the outside of the pipe. Pipes manufactured by these methods are called "enhanced pipe." Best naked tube evaporators used today amplified handsets...

|