Capacitor

Capacitor, depending on the species may be in the room but more often located outdoors. She always downstream of the compressor. The refrigerant is transported in the form of hot gas from the compressor discharge and leaves it in liquid form.

Condenser heat exchanger, which removes heat from the cooling system. In the process, she receives a hot, high pressure refrigerant gas from the compressor and turns into a liquid at low temperatures. Heat from the refrigerant is transferred to the air or the water flowing through the condenser coil.

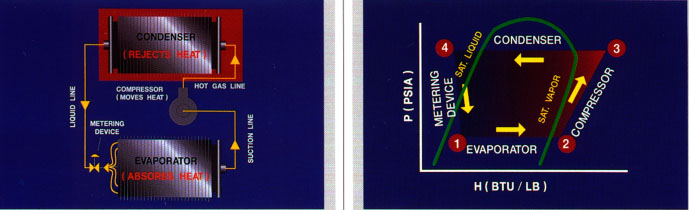

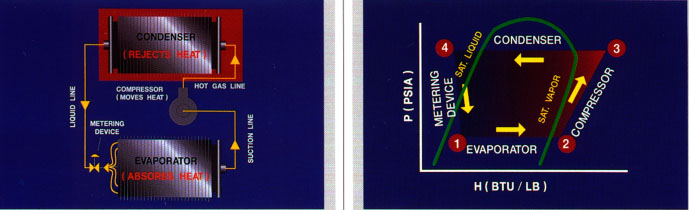

ln third module GTAC right Refrigeration Cycle, we have shown as a function of four main components of the refrigeration system can be marked on pressure-enthalpy (P-H) chart. This allows us to see, at first glance, changes of pressure, the saturation temperature and enthalpy of the refrigerant gas, as it passes through each of the four components. This P-H chart shows that the capacitor takes in the high temperature and pressure superheated gas from the compressor, in accordance with paragraph 3, and removes some of its heat.

Pressure in refrigerant circuit is almost constant, but there is a significant reduction in its enthalpy. In the process of gas changed fluid. He leaves the condenser in point 4, as high pressure, the relatively high temperature, supercooled liquids, which will move on the liquid line on the meter.

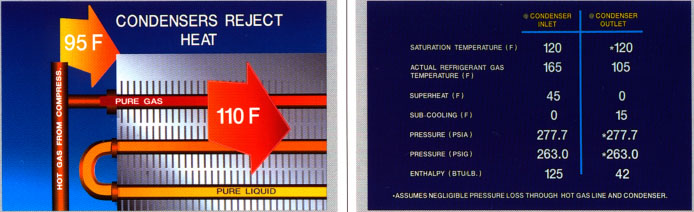

Each of the multiple refrigerant circuits, or pathways, the capacitor is running simultaneously. Shown here is one circuit inside the air cooled condenser. Fins that increase the square surface of pipes for improvement of heat exchange, have been removed to make it easy to view what is happening inside the condenser tubes. Disposal of gas from the compressor is piped through the hot gas in the hot gas title of the capacitor. Title distributes it to a few circuits, as shown here.

Gas enters circuits and passes back and through the coil. During the heat is rejected from the hotter the gas refrigerant through the walls of the pipes, air cooler (water, water-cooled condenser), passing over the surface of the heat exchanger. Refrigerant as it cools and condenses, changes from a gas to a liquid. The liquid is collected in a liquid header attached to the exit of each circuit, and passed to the input of the measuring device using the liquid line.

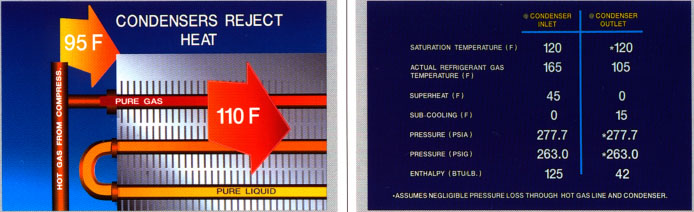

This table shows the typical effect of air cooled condenser for R-22 with an outside temperature of 95F. We have assumed that there is a differential pressure of the refrigerant from the time he leaves the compressor until she leaves the condenser. Actually, there will be a slight decrease in pressure caused by the flow resistance in the hot gas line and voltage capacitor itself.

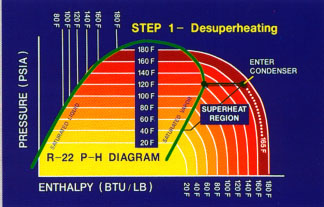

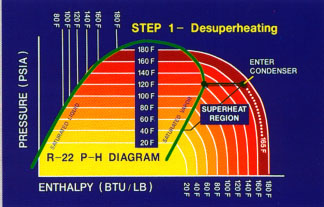

Heat exchange is carried out by a capacitor consists of three stages: cooling, condensation and hypothermia. The first step is the removal of overheating of the refrigerant entering the condenser. It is the sensible heat transfer process, as the temperature falls to saturation without changing the state. Gas from the compressor discharge enters the condenser under pressure condenser. This pressure corresponds to 120F saturation temperature shown here is for P-H schema. Actual temperature of the gas is 165F, which as you can see, that occurs to the right of the saturated vapour lines in the superheated gas chart area. The refrigerant gas moves to the left in the diagram, losing heat, and reaches saturated steam gas curve. Decrease in enthalpy of the refrigerant in this process is about 14% of the total change that occurs in the condenser.

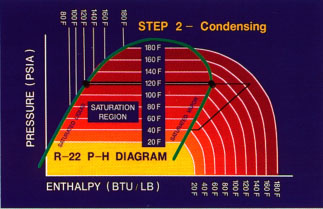

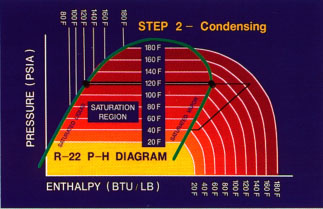

In the second step, the saturated vapor turns into a saturated liquid condensing at a constant temperature. This latent heat transfer process requires the majority of the surface of the condenser and rejects the vast majority of heat from the system. This change state which we call "condensation is finished when the refrigerant reaches the state of saturated liquid. Decrease in enthalpy caused by condensation of refrigerant vapour saturated liquid is about 81% of the total change that occurs in the condenser.

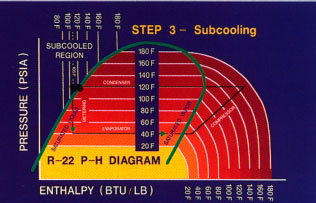

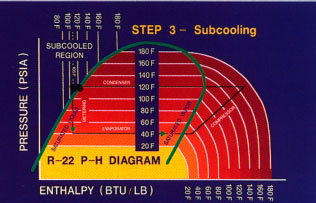

In the third and last step, saturated liquid is reduced temperature at constant pressure, thus producing a refrigerant sub-cooling. It is the sensible heat transfer process. Saturated liquid, produced by condensation process continues to lose heat, and continues to drop in temperature at about the same pressure of condensation. In supercooled region, temperature lines vertically, so the refrigerant temperature drops quickly as the enthalpy of the refrigerant continues to decrease. The decrease in enthalpy, induced hypothermia saturated liquid is only about 5% of the total change that occurs in the condenser.

Even hypothermia performs only a small part of the total heat rejection, it is important for two reasons. First, it ensures the normal functioning of fluid metering device and the evaporator. Secondly, he adds approximately 1/2% of the overall system cooling capacity in the degree of supercooling. Normal air conditioning system provides about 15 degrees hypothermia peak (design) of power. This results in about 7 1/2% (15F x 1/2% per degree) of additional capacity for what can be expected from the system without hypothermia. While most systems run hypothermia in the capacitor, it can also be done using a separate downstream of the heat exchanger...

|