Packaged Liquid Chillers

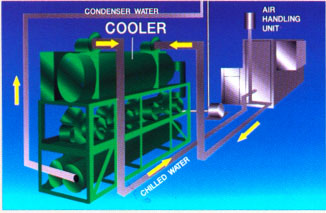

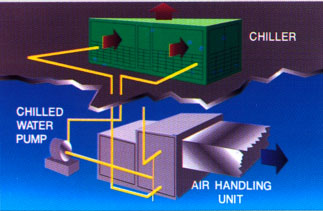

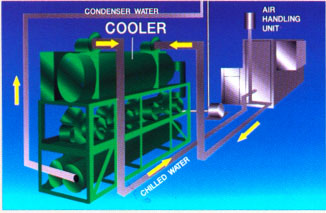

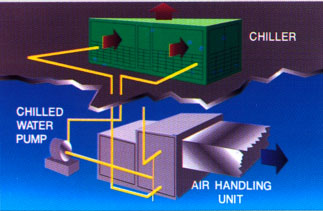

Hmm liquid cooling system includes all four components of the cooling system. Evaporator in chiller is called the refrigerator and liquid metering device can be a float valve. Coolers are used to supply chilled water cooling coil(s) all-air systems, or fan coils on all water supply system. Chiller can be purchased as a complete, factory-assembled package, or it can be selected and assembled, component by component, in the field. As with other products, the growth of labour costs for the design and installation increased the popularity of packaged refrigerators in all range of capacities. Some manufacturers produce packaged plants by as much as 20,000 tons of cooling capacity.

Name hmm reflects the type of compressor it uses. Packed reciprocating chillers use piston type (reciprocating) compressors. Traditionally, this type was used for jobs requiring less than about 120 tons of cooling capacity. Today, however, reciprocating chillers are becoming increasingly popular on the work of approximately 280 tons in connection with the improvement of partial load of the economy.

Shown here reciprocating chillers with water cooled condenser.

Water-cooled chillers installed inside the building. Heat from the condenser deviates from the water flowing through it, and building a cooling tower, which rejects heat from the outside air.

Air-cooled reciprocating chillers are also available. They are very similar air-cooled condensing units, but use a water pipe, and not for refrigerant because the whole system of cooling unit is self-contained. Bags, air cooled design allows hmm be the roof or the ground outside the building. This organization offers the same benefits as and YAC equipment. Here he depicted the chilled water in the heat exchanger one unit at all air. It is, as a rule, will deliver a number of ventilation installations like this.

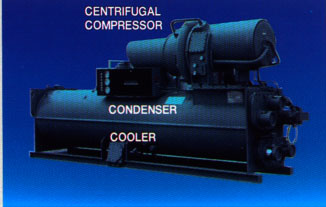

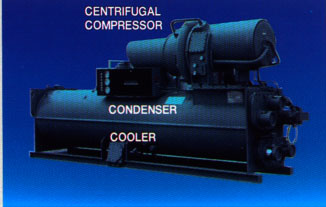

Centrifugal chillers are used in the vast majority of jobs over 100 tons of cooling capacity. They got their name from the compressor type they use. Instead of compressing the gas-refrigerant : pistons, piston compressor does, centrifugal compressors uses the impeller wheel, for gas compression. Centrifugal compressors are usually uses one or more wheels, rotating at high speed (about 3 000 - 20 000 RPM) to accomplish its task. The distinctive appearance of the centrifugal compressor makes it easy to discover. Shown here is water-cooled centrifugal both the cooler (evaporator and condenser in a single chassis, or shell. On this model, the radiator is at the bottom of the chassis, while the capacitor is on top. Two internally separated with a partition between the capacitor plates and cover. The compressor is mounted on the upper part of the body on this model.

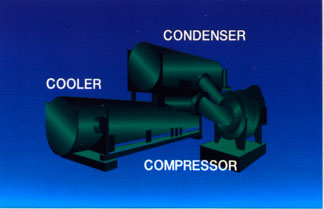

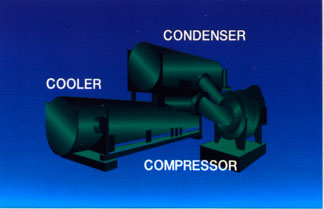

Here centrifugal chiller that uses a separate shell for condenser and colder than the one which contains both components. Again, the heat sink on the bottom, and the condenser on top. Large-diameter pipes, connected to the compressor suction line coming from the refrigerator. Low temperature, low pressure gas from the cooler is in the centre of the first centrifugal compressor wheel.

Both photographs illustrate the machines that are installed inside the building. They use water-cooled condensers and cooling towers to reject the building heat from the outside air. This is a normal situation for centrifugal chillers, although some manufacturers produce air-cooled centrifugal chillers for outdoor installation...

|