Construction of scroll compressors

Scroll compressors are usually designed as a welded joint sealants. As in the case of piston and rotary hermetic welded construction, engine and run vertically drive shaft. In contrast to the other two. scroll compressor has its own motor below the compressor. Vibration isolators, if required, usually mounted on the outside of the compressor casing. Scroll-compressor requires neither suction nor exhaust valves, because he, naturally, resists the refrigerant flow back. The scroll has the least number of working parts of any design and is known for its efficient operation, even in applications such as heat pumps and commercial refrigeration jobs that require large changes in the pressure of the refrigerant.

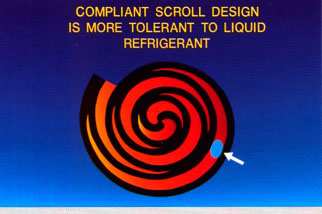

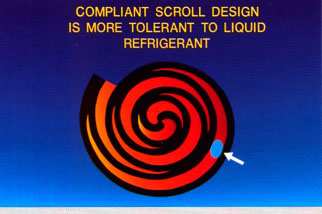

"Agreeable" select a design allow bus to the gondola from the normal position temporarily when liquid refrigerant (floodback) enters the compressor. The scroll compressor is most popular for commercial refrigeration and air-conditioning systems that use compressors from 5 to 10 tons of cooling capacity. It competes with bolted and welded hermetic reciprocating compressors for this market. As reciprocating compressors from 5 to 10 tons, scroll compressors often take advantage of the on-off Cycling and motor speed control power management.

..

|