Screw compressor

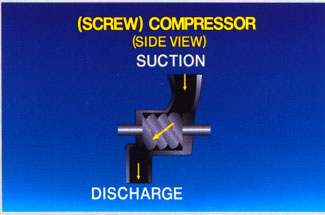

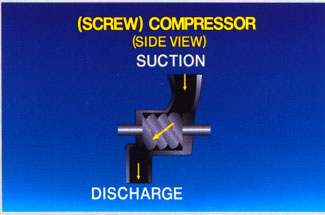

Viewed from the end, screw compressor has two screw (screw-shaped) rotors. One man flow, while the other women. Their shape allows them to compress REFRIGERANT gas as thread two screws through the grid. Compressor motor drives the rotor, which, in turn, manages the woman rotor.

Design pictured here has four tabs on the rotor and six women. Thus, the rotor rotates faster than the female.

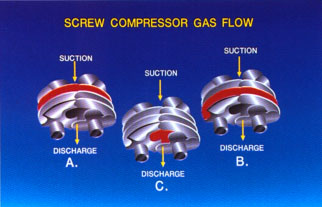

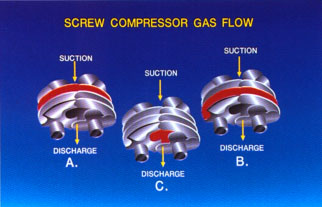

This visual shows the movement of the refrigerant vapor from suction, discharge screw compressor, and look at it from above. Point of view, the pair entered the zone of the compressor suction and was trapped between the two lobes of the rotors and compressor cylinder walls. Many samples of how to use the oil injection system to seal the gap between the rotors and cylinders. Thread forms the boundary separating a few of the combustion chambers, which are moving down through the compressor at the same time.

Only one such chamber, shown here, to simplify.

Due to B, the gas was advanced in the compressor, combustion chamber is somewhat reduced in volume. This is the beginning of the compression process. As shown in view C, compression space becomes smaller and smaller until the gas enters the compressor discharge fully compressed.

This side view shows the overall pattern of the gas refrigerant to flow through the screw compressor from his suction of his class.

Both reciprocating and centrifugal compressors, screw compressors are sold in both open and sealed styles. Motor and drive shaft, as a rule, work horizontally with a screw compressor. With the pumping of continuous action, screw compressors, usually run smoothly. Vibration isolation fixing attached outside the compressor casing.

Screw compressors have been introduced in recent years competition with large reciprocating compressors and small centrifuges for refrigeration and Airconditioning markets. They are used in industrial and commercial workplaces. They range in capacity from 20 up to 750 tons. They are especially well suited for high pressure applications such as refrigeration and heat pump work.

Capacity

Capacity control compressor screw can be done by using variable speed motor with a variable speed drive, or slide valve in the suction area of the compressor housing.

Ability to manage slide actually sliding seals. This depends on the performance of the compressor by changing the point where suction lures vapor and begins to compress it as it moves through the rotors. He will hold wide variations compression ratio without overheating, as the piston constructions are prone to do. It will also handle large differences in flow volume without problems with unstable operation, which is sometimes a problem for centrifuges...

|