Repair Of Air Cooled Condensers

Capacitor leakage can be restored. First clean the condenser and flash inside the tube with the refrigerant. If brazed joint flows, cleaning the inside seam. Then put flux, heat it, and to make joint apart.

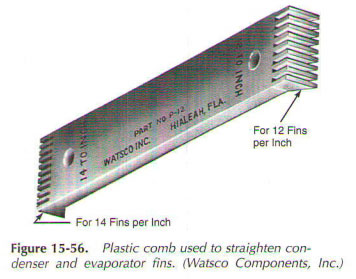

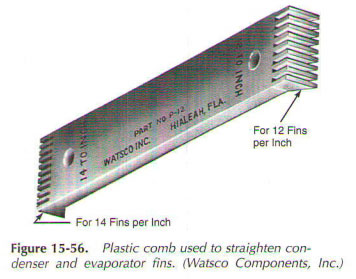

Clean soldered surfaces, RSS male part of the joint. Then assemble, collaborative, and soldering. Removal of flux. If the handset is cracked, remove the damaged part and replace with a new segment. Solder the new part. Fins may be corrected by a fin comb to figure 15-56. To check the condenser, connect one end of the capacitor. Connect the refrigerant cylinder to another end. Increase the vapour pressure of the refrigerant in the condenser and leak testing. Return refrigerant following the leak test. Use one of the following methods:

- Bubble test.

- Halide torch.

- Electronic leak detector.

- Immerse capacitor in the water.

Inspect the fittings (and flares, if used). These connections must be in good condition.

..

|