Oil Control Systems

Because they should be kept lubrication, compressors operate in oil. A certain amount of this oil leaves the compressor with refrigerant vapor. It is important that this oil prevent movement through the system. Various devices are intended for oil collection and return it to the compressor. The majority of industrial ventilation and conditioning systems use one or more of the three main oil management components. They can use the oil level regulator, the oil tank and oil separation.

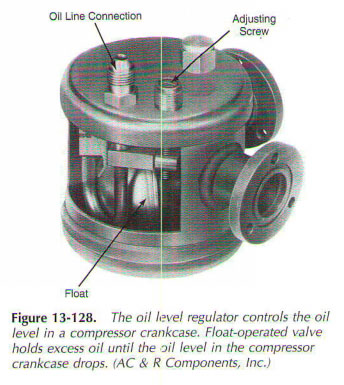

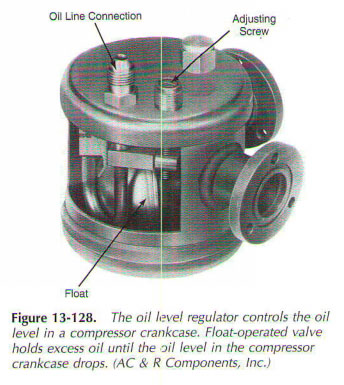

Oil level regulator controls the oil level in the compressor. It is commonly used float-type mechanism. This allows the flow of oil in the compressor, only when the float indicates that the oil level is low. Oil tanks in the system has a dual purpose. It contains compressor oil supplies and regulator draws from it, to pour the oil in the compressor. Spilled oil into the separator is returned to the tank until it is needed. Oil reservoir may contain two observation glass for monitoring the oil level. Oil tank also contains flares for the addition of oil in the system.

Refrigerating systems work best when oil is kept at the proper level in the compressor.

Oil in the evaporator and condenser reduce the efficiency of the device. It is important to keep the oil circulating in the refrigeration installations. It thickens at low temperatures and it becomes difficult to move from the evaporator.

Oil separators remove the fat from the hot compressed steam as the pair leaves the compressor. The oil is separated, because the vapor flow slows down as it enters the separator. Oil will collect in the separator, until it reaches a certain level. Then, float needle valve opens and the oil return into the compressor crankcase.

Oil separators can be placed between the compressor and condenser. The separator is isolated to prevent it from acting as a refrigerant in the condenser. Otherwise he would pass the heat to the surrounding air. Many oil separators are in working condition (bolted construction). The hermetic systems, oil-a return line, as a rule, is connected to the suction line near the motor of the compressor.

The liquid refrigerant may collect in the oil separator during long cycles or for a long manual shutdown. The liquid refrigerant is returned along the line of oil return into the compressor. This can lead to pump the oil, resulting in damage of the compressor. Non-return valve on a steam output of oil separator will reduce this danger. Filter " in the oil return line will help to preserve the pure oil.

Solenoid valve on oil return line is sometimes used. This allows the oil or refrigerant to return to the crankcase during cycles. The thermostat controls the solenoid. The thermostat will be closed only when oil separator warm (100F-130F [38C to 54C]).

.. ..

|

..

..