Ice Maker Management

Automatic ice-cube or flake ice makers for additional refrigerant and motor control. They have the controls in the trash, to halt the system when the tank is full. These controls switch off the machine until some of the ice is removed. Devices, used include:

- Mechanical levers

- Temperature controllers

- Photo sensors

Mechanical type has a lever or the diaphragm. When the lever or aperture nestles accumulated ice, he opens the switch and stops the air handling unit. Temperature control disables the control unit lamp directly contacts the ice. Both controls are located in the upper part of the box with ice. Photo sensors send a ray of light in the upper part of the bunker to the receiver. When the ice reaches the top of the bin, the light beam is interrupted and the unit stops the ice provision.

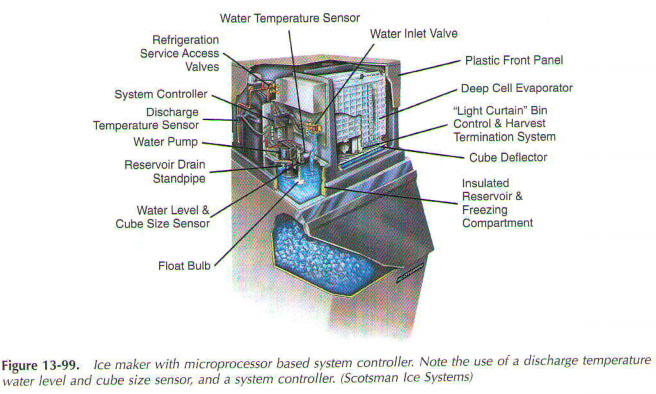

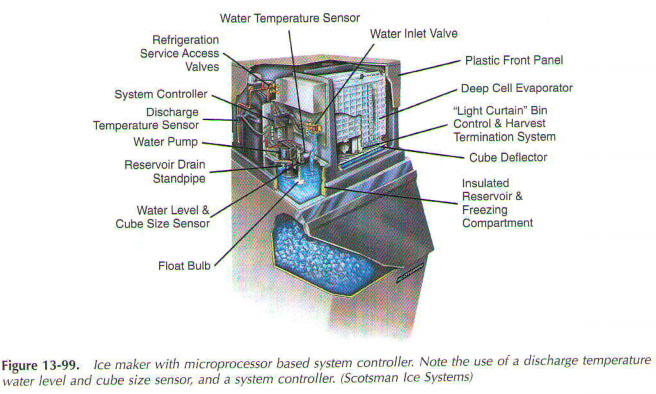

Ice machine, shown in Fig. 13-99 includes sensors for measuring the temperature of the compressor discharge, water temperature, the size of cubes and ice bin level. Fig. 13-100 shows a microprocessor-based controller is used to control and manage to do ice, and ice cleaning.

The controller receives the entrance to the block sensors and controls fill the tank of time, start time and duration of the harvest cycle, and the device turns off. Figure 13 - 101 is the basic electric circuit of hot gas defrost the ice provision.

..

|