Security Management Engine

Commercial and domestic controls differ in the fact that many of the commercial electrical systems also use the following protective equipment: high-pressure safety neckline and oil pressure safety switch. High-pressure safety devices furs built in management. It is connected the high-pressure side of the system. Often it is related to the cylinder head. This allows you to easily disable control of the system.

The pressure may prove too high of air in the system. Or, if the condenser water is turned off, the head, the pressure will increase. Bellows will expand, if the head of the pressure becomes too high. Bellows attached to it, pushed switching off the engine.

The action of high pressure safety device prevents the accumulation of dangerous pressure in the system. It also protects from destruction of the engine through the overload and overheating. Control is usually cut by 20% above the normal water pressure. The R-12 systems management set at 150 psi to 160 pounds per square inch. R-22, it is located 260 psi 270 pounds per square inch.

With R-502, he is 280 290 psi psi and R-500, it is 190 pounds to 200 psi.

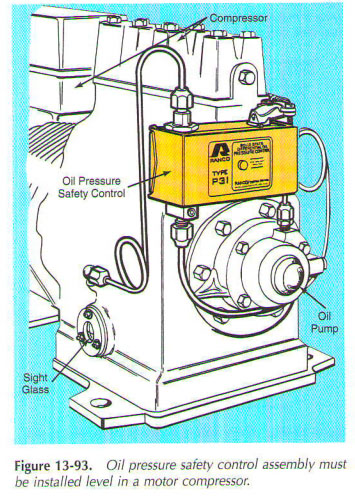

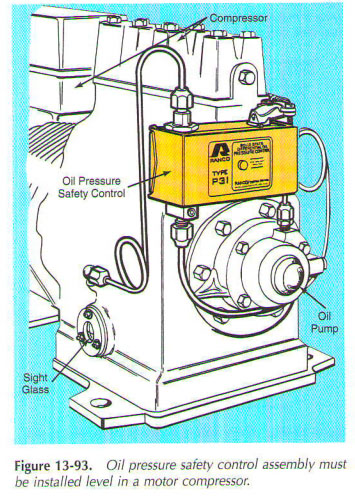

Oil pressure safety neckline will disable the power supply if the oil pressure fails or drops below normal. This differential control, using two furs. One bellows reacts on the low side pressure and other bellows falls below the required oil pressure. Large commercial systems use this type. In some systems, control points in the circuit of the electric motor of the compressor. In other cases, glasses and close current is passed through a bimetallic strip. (Or, It will be sent through a resistive heater near a bimetallic strip.) If this band is heated until the pressure returns to normal, the power will be turned off. Oil-pressure safety control shown installed on the motor-compressor Fig. 13-93.

Refrigerant level could be within safe boundaries with float switch. Float can be used for alarm or actually he can control the level of refrigerant.

The switch can be used to control the level of liquid in:

- Flooded surge drums.

- Flooded shell and tube units.

- High and low pressure receivers.

- Intercoolers.

- Transfer of vessels.

- Different types of batteries, including liquid recirculation type.

If refrigerant level is too high, the float switch closes the electric circuit. The circuit acts allow the refrigerant flow of control device. If the refrigerant is too low level float switch triggers a scheme that allows the flow of refrigerant in the system.

.. ..

|

..

..