Overload Protection

Refrigeration units and air conditioners shall be connected to different circuits from the control panel. This applies to both domestic and commercial units units. Fuse or circuit breaker in a separate chain must have sufficient capacity to permit a continuous flow of current in normal operating conditions. However, it should open circuit in the case of continuous overload more than 25%. At the moment of start, all motors draw overload current. This can amount to up to 600%. However, this overload lasts a very short time. Circuit breaker or fuse should not open circuit during this short period.

Heavier engines typically include launchers in an electrical circuit. This starter don't throw engine directly on the line. He brings to use resistance or induction unit. The device limits the current in the time of launch. This allows an increase later as the engine speed increases.

Starting relay can have some type of overload protection. The most popular type of bimetal management in series with the power supply to the engine, the resistance of the heater along with bimetallic management.

Also in the series with the power supply. This resistance unit will become hot when the motor is overloaded. Bimetallic safety devices, responsive to the heat resistance unit will bend. In the end of a bimetallic strip that will open, stopping the motor. The engine will not start until the protective device cools.

Three-phase circuit and motor-compressors are often used in quantities exceeding 1 hp. Voltage in three stages must be stored writhin 10% of each other. This prevents damage to the motor and prevent reverse mode.

Controls are used for open circuit in case the voltage at any of the three schemes changes of more than 10%. They also open when the engine starts to fall. Some controls may close the circuit again under normal conditions were met. Controls, there are usually from about 0.1 seconds to 2 seconds (if desired).

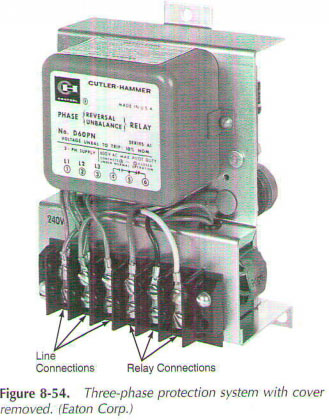

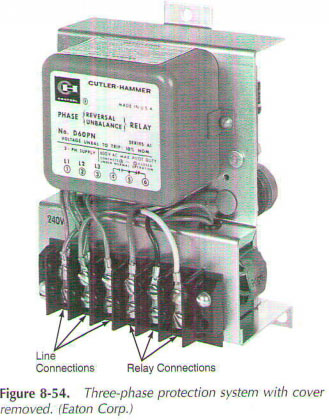

These protective devices, primarily, voltage-controlled relay. Transformers are used to step down the voltage to each potential relay. In stepped-down voltage then straightens up and fed to the coil. The same voltage, also fall under the control of the transistor. If the voltage changes too much transistor will bypass solenoid. This causes the chain to open. Fig. 8-54 shows three-phase circuit protector.

Thermistors with positive temperature coefficient (PTC) are also used in electronic device control security. PTC thermistors connected in series with the motor windings. The body temperature rises when an overload condition exists. This causes resistance thennistor to go up. Increase resistance limits the current to the motor. After thermistor and cool to a safe temperature, the engine can draw current to start again. Cm. Section 7.12 for further information concerning the protection of the engine.

.. ..

|

..

..