Pressure Control Engine

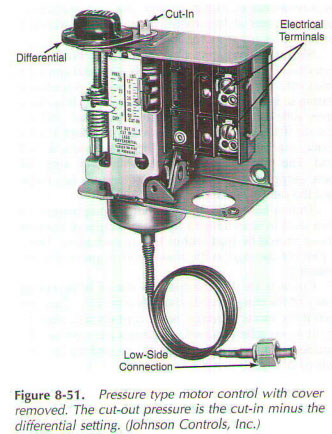

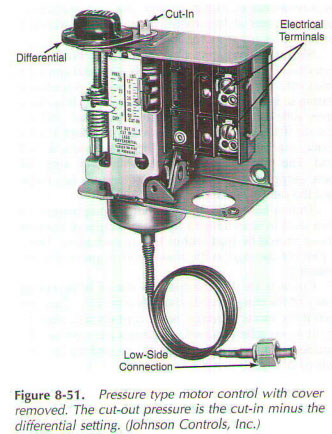

Low pressure should be moms tamed in the evaporator to allow evaporation of the coolant at low temperature. Therefore, automatic engine control can be based on pressure drops in the evaporator. This control is used on commercial systems. Bellows-operated low-pressure control is shown in Fig. 8-51.

Here's how it works: as evaporator warms, the low side pressure increases and the bellows expands. The switch is closed, and the motor starts. When the pressure and temperature become low enough, bellows Assembly contracts and contacts. Engine shuts off automatically.

Pressure motor control with cut and cut in the settings shown in Fig. 8-52. Cut and cut the controls are the only ones needed to control the differential and range. Electrical switches can be either mercury lamps or open contact-point font.

Range of adjustment will be below the cut and cut equal distance, if the screw moves (counterclockwise). Cut-out and reduce the pressure will be increased if turned in (clockwise). In the spring compression and clicks on the bellows at all times.

Differential correction will raise the neckline pressure, when turned to the right (clockwise).

It cut a type of differential adjustment. If spring tension is increased by turning the screw clockwise, it is harder for the bellows, to achieve its cut-out parameter. Spring has no effect on the context of the situation, however.

Some models of regulation of pressure are also equipped to act as a protective device. Bellows construction with pressure click on the high-pressure side of the compressor is used. If the compression pressure or pressure head should become too high, bellows expands. This movement mil open the switch and stop the motor. Such control is a safety device for the engine. This is especially necessary when the water cooling unit is used.

Low pressure control type is easily configured to work. It can also be easily changed with the help of vacuum pump and connection of the sensor after it is deleted from the device. Correction of these elements are important for the satisfactory operation of the equipment. Operation of the device depends, to a large extent on the correct operation of control...

|