Systems Of Water Cooling

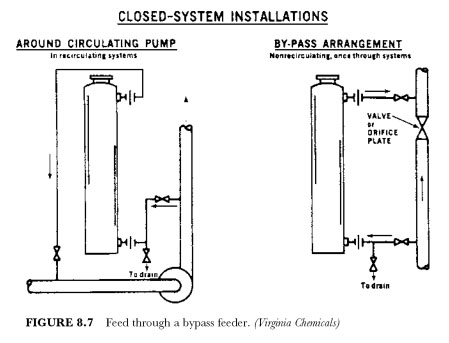

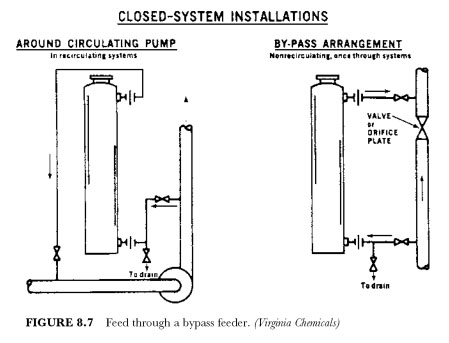

On systems of water cooling, simply follow the instructions for hot water supply systems. However, use only 3 pounds of recycled water-treatment solution for every 100 gallons of water in the system. This treatment solution must be compatible with antifreeze solutions. For an easy feeding of the initial and repeat doses of sewage, installation crystal filing in the bypass line. Crystals dissolve, as water flows through the feeder. (See Fig. 8.7.)

Installing the feeder, or in circumventing or in-line arrangement, depending on the application. Openable on the flat floor or Foundation. Standard connection with pipe unions recommended. The pipe threads should be neatly cut, clean and remove any burrs or metal fragments. Use of high-quality pipe dope. Use doping liberal.

Always install the valves on the inlet and outlet lines. Install the drain line with the valve in the bottom (input) line. Before the opening of the feeder, always closing the intake and exhaust valves. Open the drain valve of the pressure and drain as much water as you need.

Adding crystals or chemicals, molded (balls, cake etc), it is desirable that the feeders about half filled with water.

With stirring feeder necessary, use only soft wood. Stir gently, so as not to damage the coating with epoxy resin. Fill the feeder to a level above the outlet line. Coat the top opening, printing, and the grooves of the locking of the cover with vaseline or heavier lubrication.

Open exhaust valve fully. Then slowly open the inlet valve. If strangled flow required to monitor treatment feed speed, throttle valve. After the chemicals have been entered correctly, the operation of the system in the usual manner. Check the scale-remover forces in the sump color solution when using solid scale remover or with the help of test works. When the chemicals used to remove, green solution indicates a very strong cleaner. Blue solution indicates normal cleaning power. Purple decision indicates more pure need. If necessary, dip sample Carter solution in a glass, using color test. Consult the manufacturer of chemicals and their suggested color chart for precise work.

If, for example, Virginia Chemicals to remove sludge is used in solid or liquid form, the use of tests to verify the correct mixture and power solutions. Red paper indicates that there is enough clean. Inspection evaporative condenser pipes or lowering of the head pressure to normal will indicate when the unit clean. With shell and tube condensers, inspection of the inside of a water outlet pipe from the condenser will be specified size, scale, units.

After descaling completed, drain the spent solution to the sewage system. Thoroughly flush the system with at least two fillings water. Do not waste solutions for lawns or a number of valuable plants. The decision will cause damage to plants, as with any other strong solution of salt. Do not drain septic tank. Replenish Carter freshwater and resume normal operation...

|