Water-Cooled Condensers

Water is used for cooling the condensers. One method for cooling the condensers with water from the city water pipe, and then exhaust water, Sewerage, after it has been used for cooling refrigerant. This method can be expensive and, in some cases, is not permitted by law. When there is a sewer problems, limited sewage treatment plants with capacity, or drought, it is inappropriate to use this method of cooling. Recirculation for cooling water for reuse is more practical. However, in recycling, the power needed to pump water for cooling the location of the cost of functioning of the device. There are three types of capacitors and water-cooled condensers:

Two-pipe

Shell-and-reel

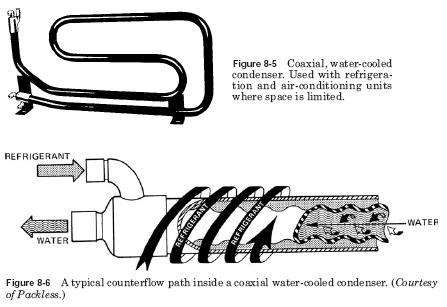

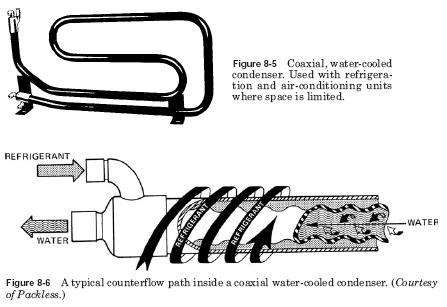

Shell-and-tube Double-tube type consists of two tubes, one inside the other (see Fig. 8-5). Water is supplied through the inner tube. The refrigerant is passed through a tube that encloses the inner tube.

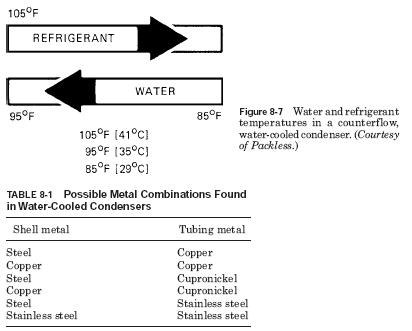

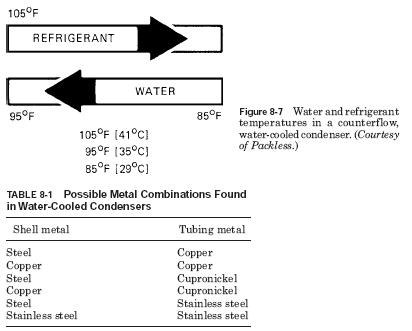

Refrigerant flows in the opposite direction than water (see Fig. 8-6). This type of coaxial water-cooled condenser are intended for the use of air conditioning and refrigeration condensing units with limited space. These capacitors can be mounted horizontally, vertically or any angle. They can be used with cooling towers. They work at the peak of the heat rejection water pressure drop no more than 5 pounds per square inch, using flow 3 gallons per minute per ton. A typical counter and a path shows the refrigerant going 105F (41C) and the water going in 85F (30C) and leaving 95F (35C) (see Fig. 8-7). Counter-swirl design, shown in Fig. 8-6, independent heat-transfer rate is high quality.

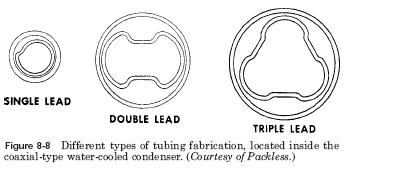

Tube design provides excellent mechanical stability. Water-flow is turbulent. This provides cleaning action, which leads cleaner surfaces. Construction method shown also has a very high resistance to pressure. Water cooled condenser shown in Fig. 8-5 can be obtained in a number of combinations. Some of these combinations are shown in Table 8-1. Copper tubing is available for use with fresh water and with cooling towers. Use Melchior presumed where saline water is used for cooling.

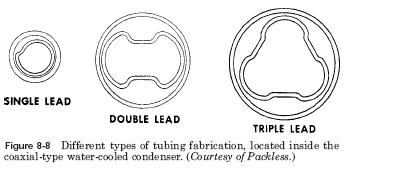

Folds in the water pipes as a result of spinning, swirling the water flow, which prevents the accumulation of deposits on the inner surface of the pipe. This contributes to the fouling of the characteristics of this type of condenser. Fig. 8-8 shows the different types of construction for a capacitor.

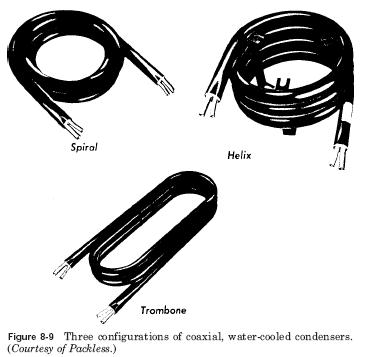

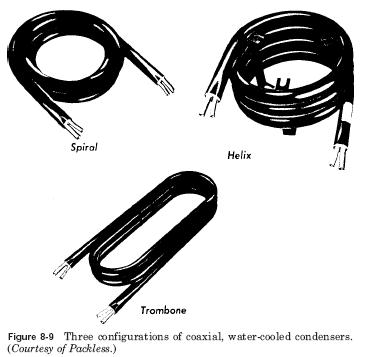

This type of capacitor may be added as a booster for standard air cooled units. Fig. 8-9 shows some of the differences in the configuration of this type of capacitor

Spiral

Spiral

Trombone Note the inputs for water and refrigerant. With the help of the tower, to furnish the water, which binds with the outer may further cooling of the condenser. Also, the water tower can be used for cooling water, sent through the inner pipe for cooling purposes. This type of capacitor useful where cooling or conditioning requirements 1/3 tons to 3 tons.

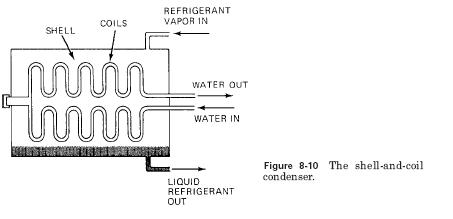

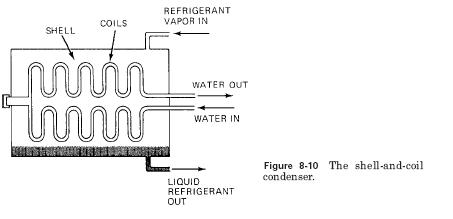

Accommodation naked ribbed tube or pipe inside a steel shell makes shelland-condenser coil (see Fig. 8-10). Water circulates through the coil. Refrigerant vapor, are entered in the shell. Hot steam contacts cooler pipes and condenses. Condensed vapour effluent from the coils and sinks to the bottom of the tank, or the shell. From there recirculation through the cold room through the evaporator. In most cases, the deployment of chemical substances in water cleanses the block. Chemicals that tend to remove the deposits that accumulate on the tube walls.

..

|