One of the screw compressor

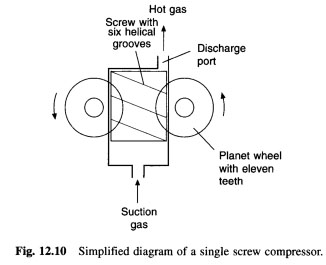

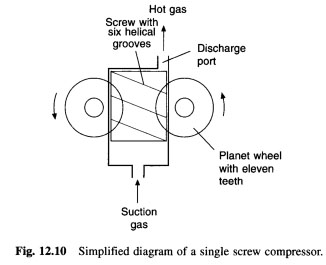

Machine consists of a single propeller or rotor), having six, carefully processed, helical grooves, assembled in cast iron, cylindrical casing with suction pressure at one end and pressure on the other. Two planetary gears (otherwise called gaterotors), each of which eleven teeth and made of special plastic, participate in helical grooves on each side of the main rotor through the slots on the opposite sides of the rotor, casing. Refrigerated in the suction chamber, you can log all six grooving screw how tooth planet wheel interaction with a groove, on the opposite side of the rotor. Gas could not pass along the grooves, which are not fully engaged with the teeth of the planet wheel because the plate in the end of the discharge of the case prevents this. However, there are two ports in the plate, allowing gas to be discharged from the two grooves, and rotation of the screw leads them opposite the hole.

In the first, suction stage of the operation, the screw rotates and gas of the suction chamber takes part one of the slots.

As the rotation continues this volume suction gas moves along the groove to participate in the next tooth on the planet wheel closes the groove of the suction chamber. The volume of gas into the groove, still on the suction pressure and is enclosed by: involvement of the tooth with the planet wheel surface of helical groove themselves, cylindrical housing screw and plate at the discharge end of the screw. In the next phase of operations continued rotation of the screw causes tooth move on a spiral groove, decrease in volumes of gas trapped and squeeze it. Finally, and the other end into the groove come opposite the hole in the plate at the discharge end of the casing, the captured gas supplied in high pressure the pressure header. This process occurs in a helical grooves on both sides of the screw and the collector receives hot, high-pressure gas from both discharge ports. From the above it can be seen that the planet wheels separate high and low pressure regions of the casing as they mesh with a screw.

The screw is driven by a motor, hermetic or semi-hermetic agreement. Planet wheels downtime and virtually no power is lost for them from the screw, except for a very small amount of friction. Friction losses are small, because the lubricating properties of the plastic planet wheel teeth, compliance and close the machining tolerances adopted. Another advantage is that bearing constraints for small and operating life can reach 200 000 hours.

The screw can tolerate some liquid feedback. Version with just one planet wheel is also used for some applications. Operation is similar. Lubricant can be injected oil, its function is for lubrication, cold and seal between high and low pressure, and intensify the potential of the mechanism of unloading. Oil separator is then needed a high-pressure refrigerant and oil cooling system is also required.

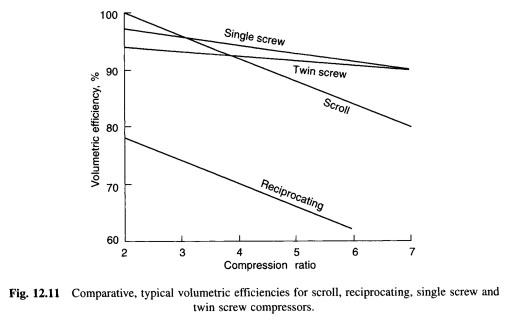

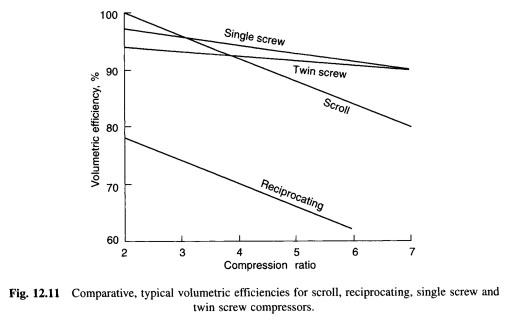

Favorite alternative is to use a liquid refrigerant, which is virtually free from oil. (There may be some small amount oil because the need for oil in the bearings.) This is injected into the compressor casing. The advantages are that no oil separator is required and no external oil cooler is needed. Since friction losses are very small planet, where the wheel teeth engage the screw, only functions impose a refrigerant for seals and cool. The stills are often fitted and volume and isentropic efficiency high (see Fig. 12.11).

Output control with the help of slide valve that changes the place where compression begins, resulting in variable displacement compressor. Actuate-piston driven by oil pressure or, if oil-free system is used, electric motor. Unloading can be proportional with continuous modulation of the slide position, or in steps.

As the water cooled and air cooled machines are available and the range of cooling capacity decreases from 15 kW up to 4500 kW, depending on the operating conditions, whether or not used lubrication oil, and use of water or air for конденсатор cooling. Low noise and vibration level, probably due to the lack of valves and small variations in the moment...

|