Refrigerating Systems. Centrifugal compressors

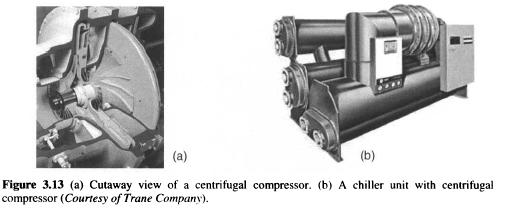

Centrifugal compressors are often used instead of reciprocating compressors for very high capacity, or for high-flow-low pressure difference of applications and designed for cooling use, in 300 kW to 20 MW range (e.g. 40010,000 tons). Centrifugal compressors also suitable multi-stage refrigeration applications, where two or more levels of compression can be included within a single body turbine with interstage gas injection between the rotors. These compressors manufacture of compression due to the high velocity of the impeller, connected to the electric engine or gas engine. Fig. 3.13a shows a cutaway view of a centrifugal compressor, which uses hybrid bearings. The inclusion of hybrid bearings in a compressor designs allows the refrigerant itself to be used as grease. Fig. 3.14b shows the chiller unit with centrifugal compressors using hybrid bearings.

Centrifugal compressors available on the market, the use of R-123 and R-22 and R-134a.

This usually requires a semi-hermetic constructions, single-and multistage impellers. In the refrigeration industry multi-stage centrifugal compressors now manufactured from cast iron, nodular cast iron and cast steel housings for discharge pressure up to 40 bar. With eight wheels in a single chassis, a compressor with capacity of 42 000 m3/h and 9000 kW. Please note that cooling system using the ammonia as the refrigerant are not available with centrifugal compressors. Only open drive screw or reciprocating compressors are compatible with ammonia, mainly because of its corrosive properties, and reactions with copper. The choice of one phase, multi-stage, open or hermetic design largely depends on the individual manufacturer's preference and application. For example, centrifugal compressors, which are limited in their compression impeller. Thus, the application to call the high temperature lifts (for example, ice thermal storage) may require a multi-stage designs. The principle of action of centrifugal compressor is the same as the centrifugal pump, but refrigerant gas is pumped instead of a liquid. Rotating impeller attaches speed of gas throwing it out. Housing slows down the flow of gas, conversion of part of the kinetic energy (speed, pressure) in the static pressure. These compressors are typically used for large refrigeration systems (e.g. from 200 kW to 10,000 kW cooling), low-pressure ratio and work with adiabatic compression efficiency up to 80%. Evaporator temperature can reach-100C.

Packed centrifugal compressors with water cooling are available in sizes from 85 tons to more than 5000 tons. The big sizes, as a rule, 1200 to 1500 tons and more, shipped in knots. Smaller sizes are available as factory-assembled package (Fig. 3.14).

Centrifugal compressors, use one or more rotating wheels to increase the pressure of refrigerant vapour at the outlet of the evaporator enough to do this are condensed in the condenser. In contrast, the positive displacement reciprocating, scroll or screw compressors, centrifugal compressor uses a combination of rotation speed (rpm) and the Council of speed to produce a constant differential pressure. The refrigerant vapor from the chiller evaporator usually prerotated using the variable inlet guide vanes. Subsequent swirling action provides the expanded portion of the power and efficiency. Vapor then type centrifugal compressor along the axis of rotation. A couple of passages in centrifugal compressors surrounded by blades extending from the compressor hub that may be shrouded for flow-path to efficiency. The combination of speed of rotation of a wheel with a diameter of combines to create a Council speed necessary for acceleration of refrigerant vapour, high-pressure discharge, where they go on the capacitor. Thanks to its high vapour permeability-throughput characteristics, centrifugal compressors, which dominate 200 tons level, where they are the least costly and most efficient cooling compressor design. Centrifuges are most often driven by electric motors, but may also be driven by steam turbines and gas engines. Depending on manufacturers design, centrifugal compressors used in packages may be 1-, 2-, or 3-stage and use the semi-hermetic or open motor with shaft seal. Fig. 3.15 shows a new type of centrifugal compressor, which was recently developed York International, providing a completely oil-free compression using magnetic bearings, especially for large refrigeration and gas compression applications. Thoroughly tested with the help of magnetic bearings S2M experience and magnetic bearing technology option removes all negative on acquisition and maintenance lubrication system. In fact, magnetic bearings improve the efficiency of the centrifugal compressor and exploitation. They are produced of different sizes and parameters. ..

|