Hot Air Furnace, Manufacturing Schemes

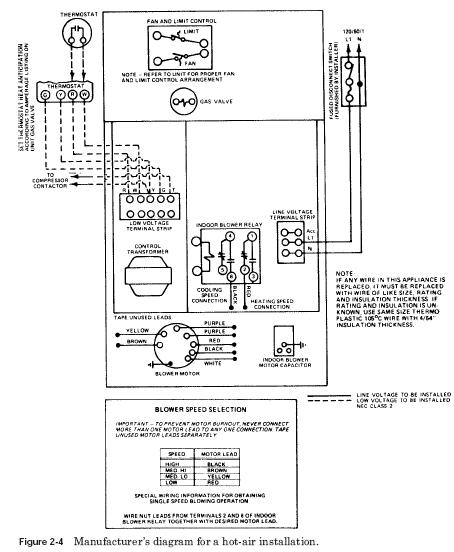

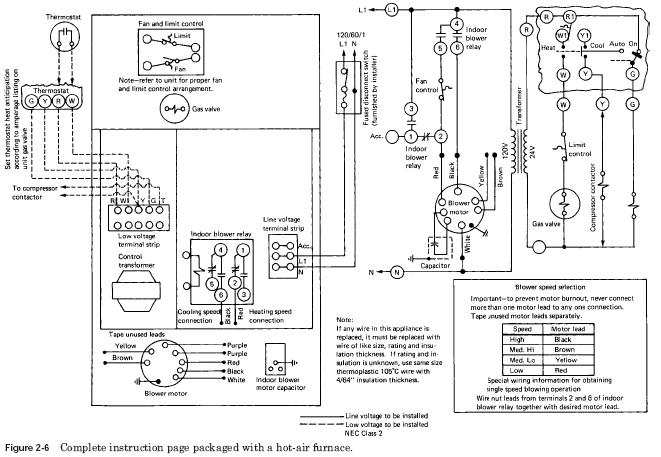

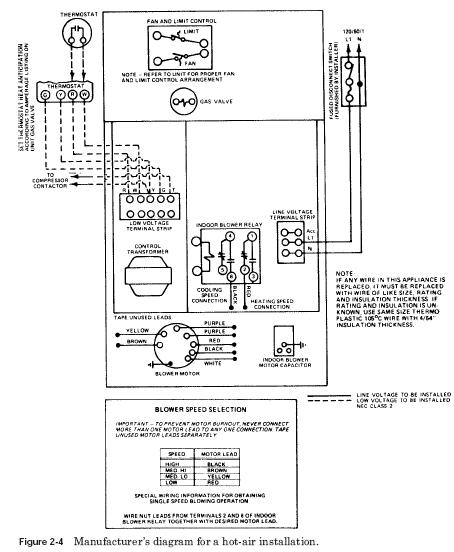

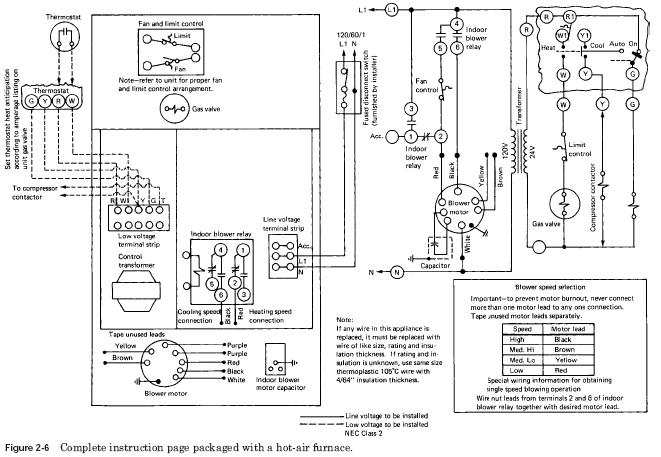

Fig. 2-4 shows as a producer represents the location of the various furnace devices. Solid lines denote the line voltage must be installed. The dashed line of low-voltage to be set when the furnace was commissioned. Motor four-speed. It has different colored leads to represent speed. You may have to change the speed of the motor to move the air in this place. Most of the engines come from the factory with a break speed selected. Speed is usually easily changed by extraction of lead from one point and place it in another if the correct color is. On the diagram Fig. 2-5, fan motor white lead is connected to one side of the 120-V line (neutral), and red and black switched to an indoor fan relay to the black cooling and red heating rate. He takes the faster the fan motor to push cold air than hot air, because cold air is heavier than warm air.

On Fig.

2-5, contacts thermostat labeled R, W, Y, and G. R and W are used for the thermostat in the chain. It can be switched from W Y manually by moving heat-cool thermostat switch in position cool. Notice in figure 2-5, the indoor fan relay coil is in the circuit all the time, when the automatic switch on the thermostat is set to " on". Diagram also shows the cool position has been selected manually, and contacts of the thermostat will complete the circuit when it goes from W1 to Y1.

On Fig. 2-4, please note that for low voltage terminal block has This General the low voltage side of the transformer. On Fig. 2-5, T is shared by the low voltage side of the transformer secondary winding. On Fig. 2-4, T terminal is connected to the compressor contactor wire run from the terminal to the contactor. Note that the other wire to the contactor runs from Y to the terminal block. Now back to Fig. 2-5, where Y and T terminals are displayed as connection points for the compressor contactor. You are able to apply the schema on the device itself? Gas valve wire with wire T terminal strip attached to one side of the solenoid, and the wires from the limit switch to the other side of the solenoid.

On Fig. 2.6 shows how the wiring diagram supplied from the factory. It is usually located inside the cover for the cold air return. In most cases, it is pasted on the cover so that it is convenient for a person working on the stove whenever there is a problem after installation.

..

|