|

|

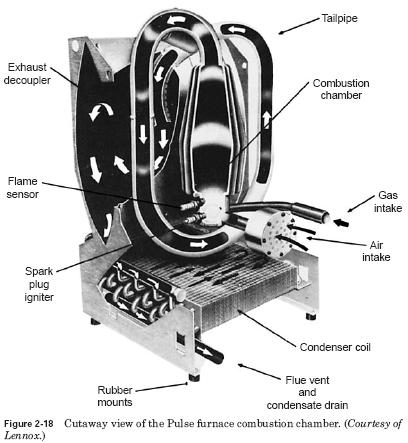

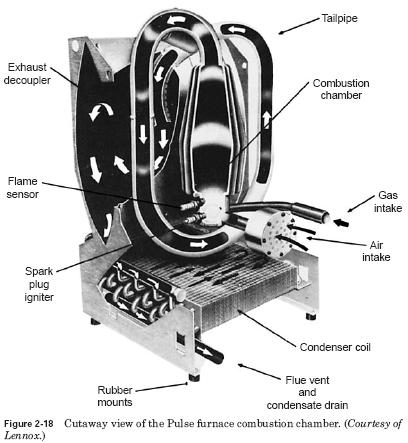

High-Efficiency Furnace Combustion Process

The process of pulse combustion starts gas and air are introduced in a closed combustion chamber spark igniter. Sparks from the plug ignition of the air-gas mixture, which, in turn, causes positive high blood pressure, that closes the gas and air intakes. This pressure, relieves himself, forcing the combustion products of the combustion chamber through the exhaust pipes in the heat exchanger the exhaust decoupler and in the heat exchanger. As combustion " dummy", its pressure becomes negative, drawing in air and gas for ignition of the next pulse. At the same moment, the part of the pressure pulse is reflected from the exhaust pipe at the top of the combustion chamber. Flame residues of the previous pulse combustion light a new gas-air mixture in the chamber, continuing the cycle. After the combustion is started, it feeds on itself, allowing to purify air blower and the spark plug should be disabled. Every impulse of the gas-air mixture is ignited in the amount of 60 to 70 times per second, producing 1/4 to 1/2 BTU / pulse combustion.

Almost complete combustion occurs with each pulse. Due to these series of fires creates great turbulence, which makes the combustion products through the entire heat of the Assembly, resulting in maximum heat dissipation (see Fig. 2-18).

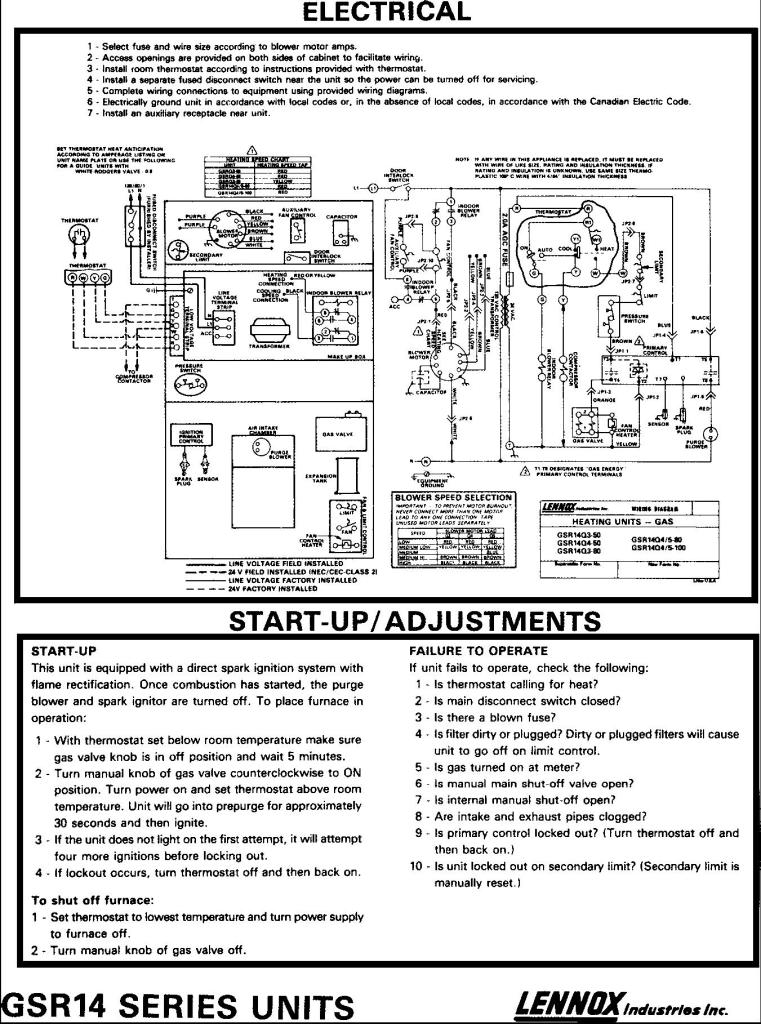

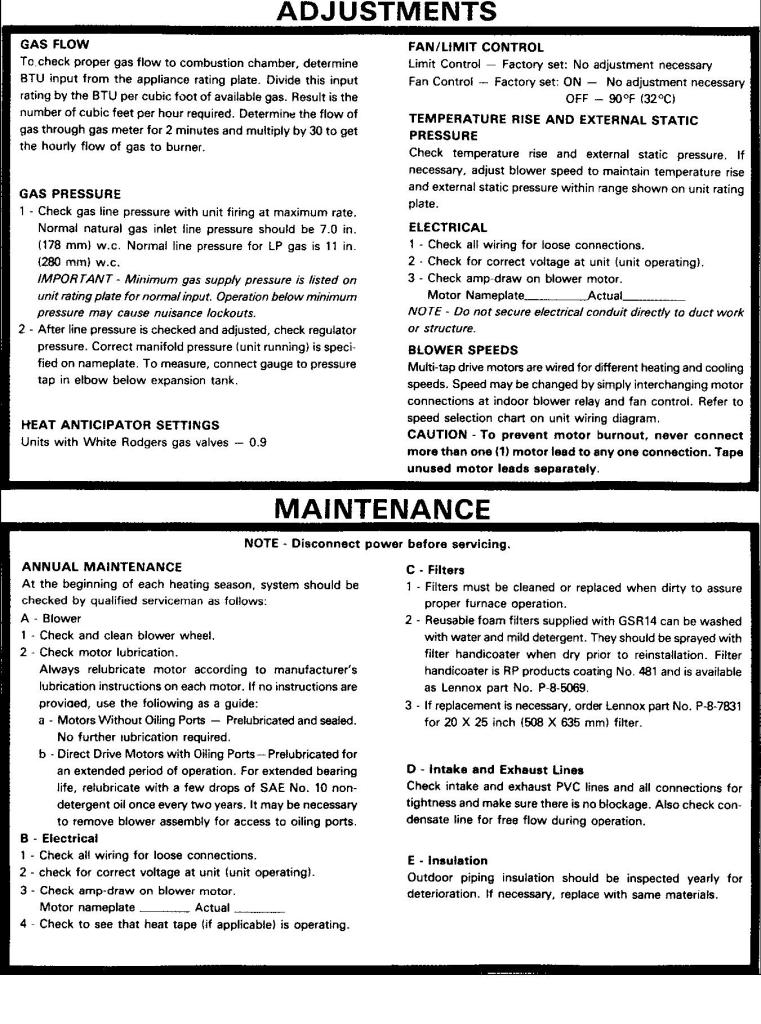

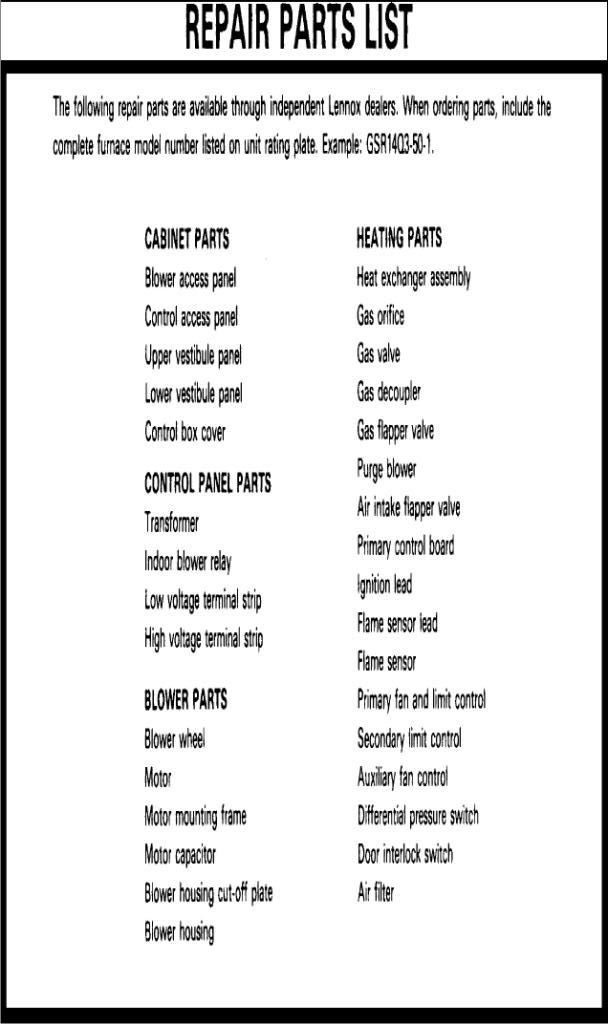

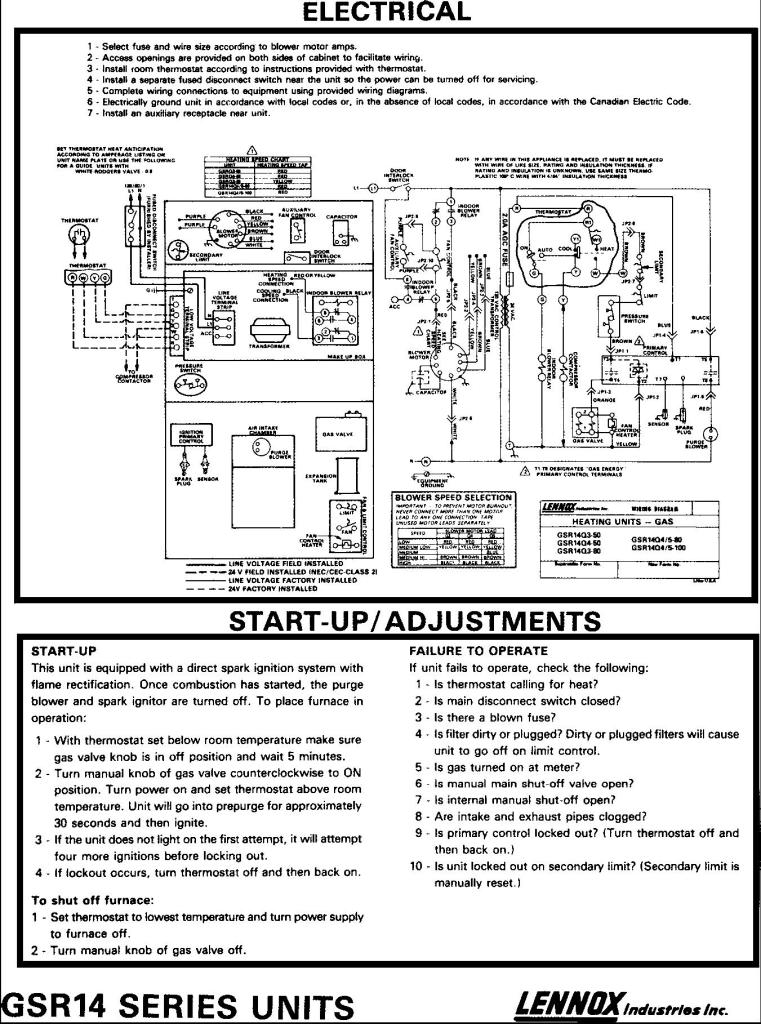

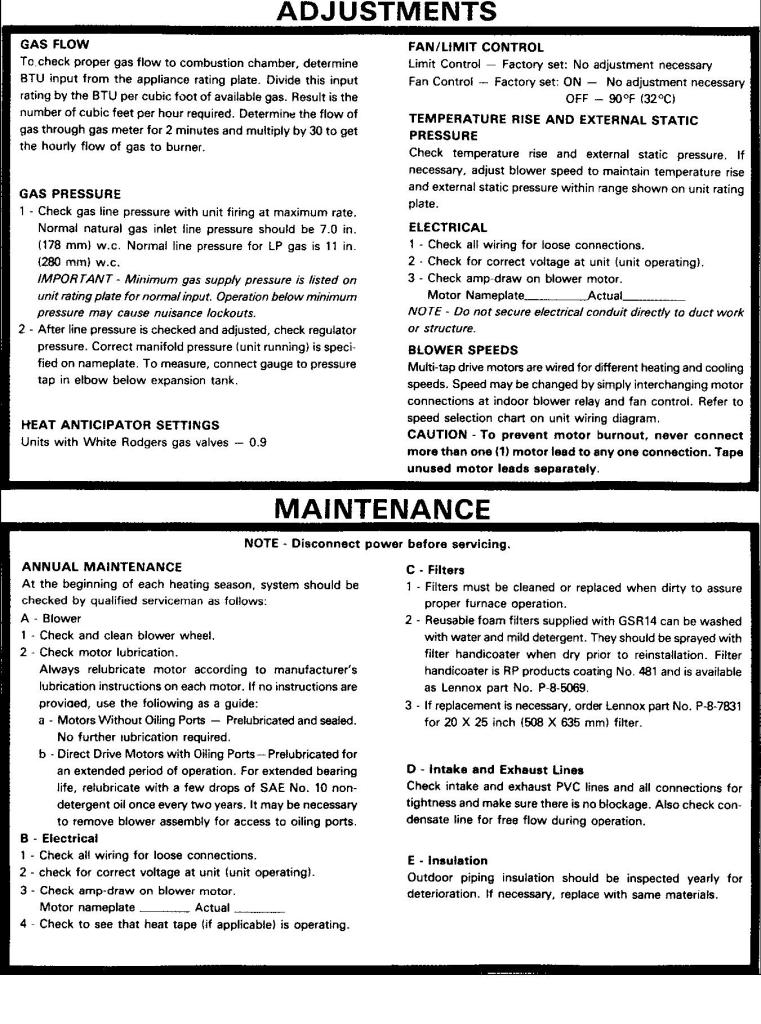

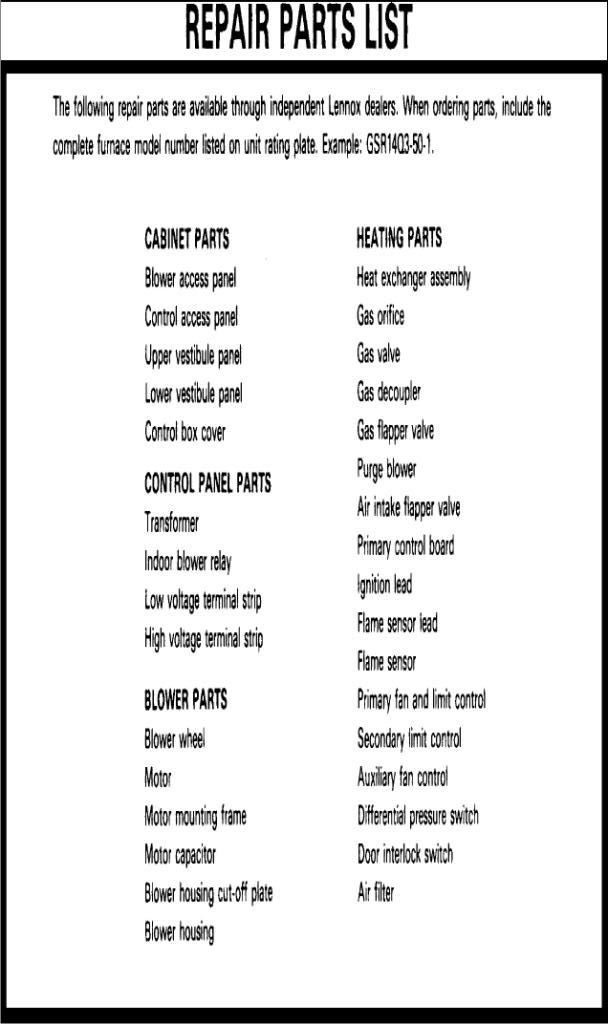

Commissioning for GSR-14 C series Lennox Pulse furnace, as well as maintenance and repair details, see Fig. 2-19.

..

|