Refrigerating Systems. Vapor Compression Refrigeration Systems

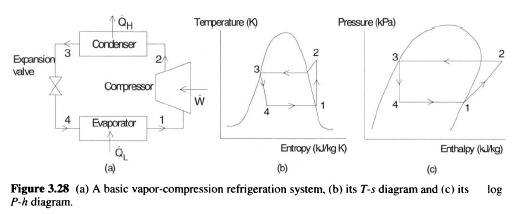

In practical applications, a vapor-compression cooling system are the most commonly used cooling systems, and each system running compressor. In the base vapor compression refrigerating cycle as shown in Fig. 3.28, four major thermal processes are as follows: Evaporation

Compression,

Condensation and

Extension.

Evaporation

Unlike freezing and melting, evaporation and condensation occur in almost any combination of temperature and pressure. Evaporation is a gas escape molecules from the liquid surface is carried out by means of absorption of a large amount of heat, without any change in temperature.

Fluids (e.g. refrigerants) evaporate at all temperatures, increased evaporation occurring at high temperatures. Evaporated gas pressure is called the vapor pressure. As the temperature of the liquid rises, there is a large loss of fluid from the surface, which increases the pressure of steam. In the evaporator refrigeration system, low-pressure cold refrigerant vapor is brought into contact with the medium or substances for cooling (i.e. radiator), it absorbs the heat, and, therefore, furuncles, producing low pressure of saturated vapors. Compression

With the shaft of the compressor, increases the pressure of the refrigerant vapor received from evaporator. In addition heat can play a role in raising pressure. The increase of gas pressure raises the boiling and condensation temperature of the refrigerant. When the gaseous refrigerant is in a fairly short of its boiling point is higher than the temperature of the heat sink. Condensation

Is the process of converting a pair of liquid by extracting heat. High-pressure refrigerant gas, which transfers the heat energy absorbed by the evaporator and work energy of the compressor is applied to the capacitor. Temperature of condensation of the refrigerant is slightly higher than the radiator and, therefore, the transfer of the heat of condensation of high vapour pressure of the refrigerant high-pressure of saturated liquid. As the source of heat is cooled by heat pumps heat sink. Instead of using a capacitor for the emission of heat to refrigerant vapor could be emitted, but this method is inappropriate. Condensation of the refrigerant gas is re-used at the beginning of the next cycle. In some practical applications, it is desirable that the condenser is cooled by the refrigerant further, below the temperature of condensation. This is called hypothermia, which is usually observed in capacitor to reduce flicker during the refrigerant pressure is reduced in the throttling device. This method provides reduction of the amount of gas at the inlet of the evaporator and, thus, to improve system performance. Expanding

The condensed liquid refrigerant back to the beginning of the next cycle. Regulation devices such as valve orifice plate, or capillary tube to the expansion process is used to reduce the pressure liquid refrigerant low pressure, level and temperature of the refrigerant boiling point below the temperature of the heat source. Energy loss through this pressure reduction shall be compensated by an additional energy costs in the boost phase.

On Fig. 3.28Р° shows a diagram of main steam-compression refrigeration machines. For a better understanding of the cooling cycle is shown temperature, entropy (7-5) and pressure-enthalpy (log P-h) diagrams, as they are presented in Figures 3.28b and 3.28c. Under the steps above, the functioning of this system is: (1-2) Reversible adiabatic compression. Evaporator with low vapor pressure of the refrigerant comes to the compressor and compressed into a condenser by reduction of volume and the increase in pressure and temperature.

(2-3) reversible heat rejection at constant pressure. From the high-pressure compressor refrigerant steam enters the condenser and liquefied by the use of water or air.

(3-4) Irreversible expansion at constant enthalpy. From the condenser, the high-pressure of saturated liquid refrigerant passes through an expansion valve, and its pressure and temperature drops.

(4-1) reversible heat addition at constant pressure. From the expansion valve low pressure refrigerant liquid enters the evaporator. It boils here and in the process absorbs heat from the environment, thereby providing a cooling effect. As shown in Fig. 3.28, the main components, a simple steam-compression refrigeration machines, as explained above, is: Evaporator. This product where the heat exchange for cooling, and so it boils liquid refrigerant at low temperature, which causes the refrigerant absorbs heat.

Suction line. This is the pipe between the evaporator and the compressor. After the liquid is absorbed heat, suction line carries refrigerant in the compressor. In this line, refrigerant superheated gas. The compressor. This device separates the side of low pressure systems from the high pressure side and has two main objectives: (i) to remove vapour at the outlet of the evaporator to keep in the evaporator, the boiling temperature is low, and (ii) for the compression of low-temperature of the refrigerant vapor in a small volume, creation of high temperature, high pressure superheated steam.

Hot gas discharge line. This tube connects the compressor, the condenser. After the compressor has been discharged of a high pressure, high temperature of the superheated steam refrigerant, hot gas discharge line carries it to the condenser.

Capacitor. This device is used to transfer heat, similar to the evaporator, except that his job is to drive heat, not absorb it. Capacitor changes in the state of superheated steam refrigerant back into liquid. This is done by creating high pressure, which increases the temperature of the refrigerant boiling point and remove sufficient heat to cause condensation of the refrigerant back into liquid.

In the Liquid line. This line connects condenser refrigerant management device. including the expansion valve. Liquid refrigerant should be in this line. Also, this line should be lukewarm, because the refrigerant is still under high pressure.

Refrigerant management. This last element management works as a measuring device. It monitors the liquid refrigerant, which enters the evaporator and makes sure all the liquid boiled away to the refrigerant passes to the suction line. If the liquid refrigerant enters the suction line. he enters the compressor and lead to failure. In addition to the components listed above, there are a number of additional functions, for example. liquid receiver, fittings, foot valve, discharge valve, service valve liquid receiver, which can enhance the refrigeration system in operation. ..

|