Multistage system of cooling

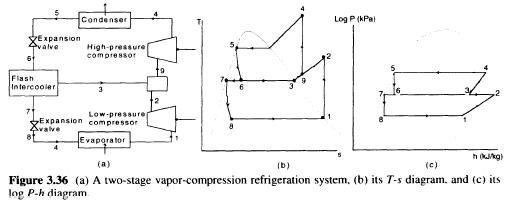

Multistage system of cooling is widely used there, where ultra-low temperatures are required, but can not be produced economically through the use of a single-stage system. This is because the compression ratio is too high to reach the temperatures necessary for evaporates and condenses the steam. There are two main types of such systems: cascade and multi-stage. Multistage system uses two or more compressors are consistently in the same cooling system. The refrigerant is becoming more thick steam as it passes through each compressor. Please note that the two-stage system (Fig. 3.36) can reach a temperature of around 65Р’C and three stages of 100VC.

Single-vapor-compression-type refrigerators are used refrigerated warehouses with a range of +10VC-30VC. In this system, on the evaporator installed within the refrigeration system and ice structural unit, as a source of low temperature, it absorbs the heat. The heat through the condenser high pressure side. In cases where large temperature and pressure differences exist between the evaporator and the condenser, multistage vapour-compression systems work accordingly.

For example, if the temperature of the refrigerator (i.e. freezer), below-30VC, severalstage compression system is required in order to prevent a high compression ratio. Some of the shortcomings of high compression ratio:

Reducing the efficiency of compression,

Increase the temperature of the refrigerant vapor in the compressor, and

The increase in energy consumption per unit of refrigeration products. Fig. 3.36a is a schematic diagram of the two-stage steam-compression refrigeration unit, which can provide temperatures below-30VC (approximately up to 50VC), and T-s and log P-h schema are shown in Fig. 3.36b and 3.36c. This system also uses the intermediate cooler air. As an example, a three-stage refrigeration systems can provide a temperature of the evaporator out-100VC. In two stages shows a block refrigerant is compressed in the first stage and after desuperheated with intercooler, further compressed in the second stage. Intercooler is used between two degrees of compression to reduce compression. In other words, a booster (first stage) compressor and gas-liquid intercooler are attached to one stage of the cycle. The intercooler subcools liquid refrigerant flow to the evaporator by evaporation part of the refrigerant after the first stage regulation. Flash gas is returned in an intermediate point in the process of compression in order to enhance the compression efficiency by cooling of superheated gas. Not only the compressor, but the set of compressors needed to use at each stage, depending on the power and temperature. In larger systems with multiple evaporators and large compression (temperature) coefficients, the number of intercoolers and compression stages yields have increased the efficiency of the system and, as consequence, growth of the COP. ..

|