Automatic Expansion Valve Principles

Thermostatic expansion Valve (TRV) Principles

Thermostatic valves are two basic types:

- Sensing bulb.

- Electrothermal.

Sensitive lamp is divided into four types:

- Liquid-charged.

- Gas-charged.

- Liquid cross-charged.

- Gas cross-charged.

In liquid-charged and gas charged elements, the same refrigerant is used in the system, and light. Cross-charged means that the sensing bulb liquid differs from system refrigerant. In the automatic expansion valve the refrigerant passes through the valve and the evaporator. The flow is controlled by the pressure in the evaporator.

In the thermostatic expansion valve, flow through the valve into the evaporator. However, it is under control and the low side of the pressure and temperature of the evaporator. Valve provides higher flow rate as evaporator packagings (warms). This reduces performance because evaporator fills (cools down) with the refrigerant.

Sensitive ball valve accumulated pressure or force the difference between the sensing bulb fur and low-pressure side.

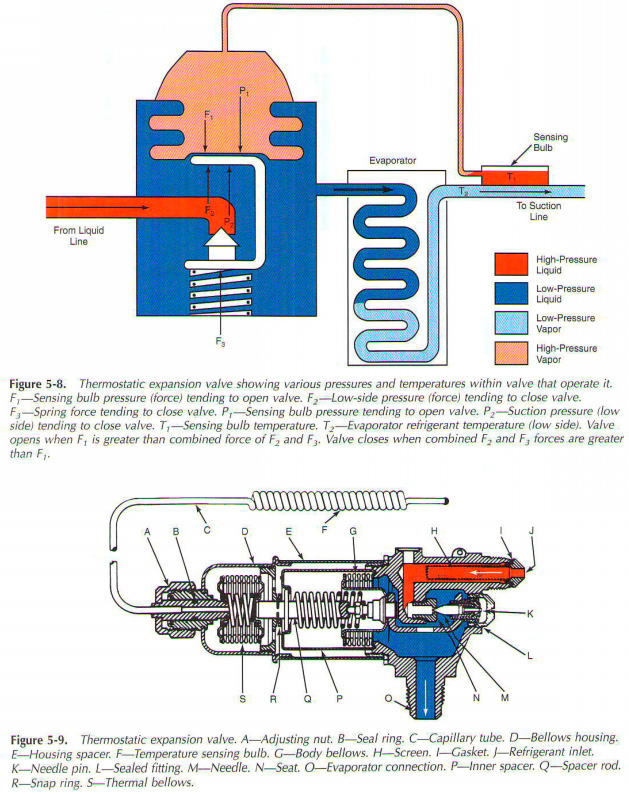

Cm. Fig. 5-8.

The unit operates, the temperature of the refrigerant in the sensing bulb, as a rule, is about 10F (5.6C) warmer than the temperature of the refrigerant in the evaporator, T2. This drop in temperature produces a variety of pressure and, consequently, different forces. This temperature difference is often described as overheated bulb above the temperature of the refrigerant inside the evaporator. Pressure sensing bulb, Px, more than the evaporator pressure, P2. Note that as the increase or decrease of temperature, pressure, will also increase or decrease.

When the compressor stops, the low-pressure side and sensing bulb pressure tend to equalize. The total expansion valve inner strength, Ft + F3, overpowers the sensing bulb force, F:. Needle forced firmly in his seat. Refrigerant flow7 stops. The needle will remain closed until the sensing bulb is overcome by the low side of the force.

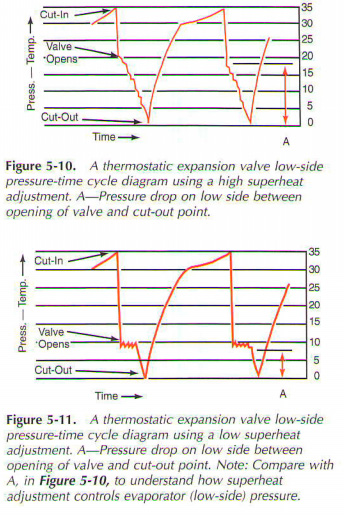

This valve-opening action must take place only when the instrument is working. If the valve correctly, he closes when the compressor is in standby mode. This will prevent the flooding of low-side with liquid refrigerant. Thermostatic expansion valve does not regulate the low-pressure side. It controls the filling of the evaporator, the refrigerant. The pumping action of the compressor sets the low pressure side. Fig. 5-9 illustrates the bellows thermostatic expansion valve.

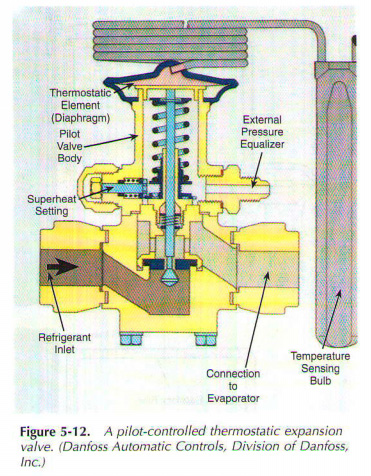

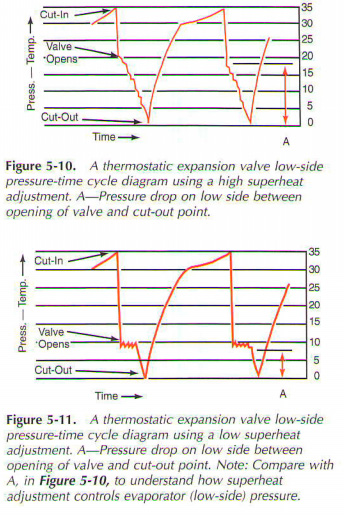

The valve can be adjusted so that the needle seats, while the instrument is working. The needle will then close, even if there is a big difference in temperature (about 15F or 8.3C) between the refrigerant in the evaporator and that the sensing bulb. This is shown in Fig. 5-10. In the evaporator, liquid refrigerant will not reach the sensing bulb place in this case. Only low-pressure steam will be cold enough to reduce the sensing bulb temperature (and, consequently, pressure) to the endpoint. Needle closes to the evaporator becomes a full refrigerant liquid droplets. Evaporator will be sorely lacking. If the valve is adjusted in the other direction, the arrow moves away from the seat. Temperature sensing bulb refrigerant will be closer to the evaporator refrigerant, about 5F 7F (2.8C to 3.9C). Cm. Fig. 5-11.

Evaporator would then become a full drops of liquid refrigerant to bring the temperature (pressure) difference down to this value. Evaporator will be flooded. A few drops of water may even go into the suction line. This can cause sweating, or freeze suction line and can damage the compressor (traffic jams).

Adjusting nut or bolt sensitive. It should not be a member of more than one-quarter of the revolution during operation of the device. The system should be provided 10-15 minutes until the next adjustment. Some thermostatic valves diaphragm use instead of furs. In any design, the valve is closed when the unit is not working.

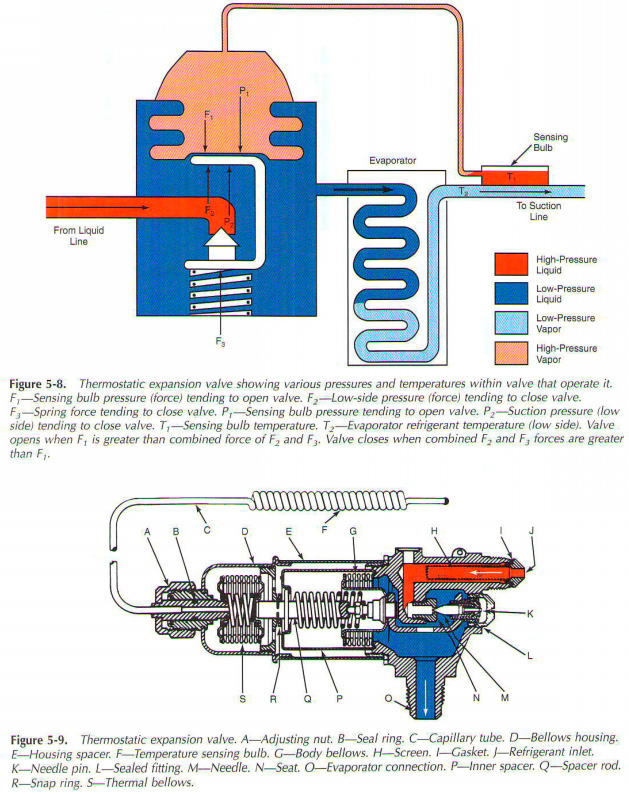

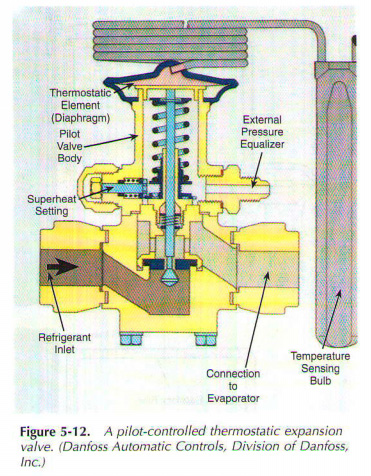

In some large refrigeration plants (50 tons or more) can use the test pilot with the, thermostatic expansion valve. In these installations, conventional thermostatic expansion valve is mounted on a very large additional valve body. The subsidiary valve provides more pressure-operated needle and holes. Ordinary thermostatic control refrigerant (pilot) regulates the pressure that manages the larger size. Fig. 5-12 illustrates one type manned thermostatic expansion valve.

Some great air conditioning system can use as many as six thermostatic valves on one evaporator. Thus, you can:

- To maintain a constant pressure and temperature.

- Make sure the evaporator is fully charging the refrigerant.

- Reduce the pressure drop through the evaporator.

.. ..

|

..

..